5G

Overview

- In the fifth-generation mobile communications system (5G) and Beyond 5G/6G, which are scheduled to be introduced in the future, a large amount of telecommunications equipment that handles radio waves with high frequencies will be introduced.

- Along with this, problems are the securing of a place for installing telecommunications equipment, the increase in power consumption associated with communications, and the increase in the amount of heat generated by antenna boards.

- By using our microcellular plastic (MCP), we can expect to increase the installation space for telecommunications equipment, increase the flexibility in installation locations by reducing weight, reduce power consumed by telecommunications, and increase the flexibility in thermal designing of equipment.

Table

- 5G communication issues and requirements for materials for radome

- Low dielectric (improved radio wave permeability) and light weight by microcellular plastic (MCP)

- Infrared ray radiation reflected by microcellular plastic (MCP) (to suppress thermal rise caused by radiant heat)

- Application of microcellular plastic (MCP) to radome for 5G communications equipment

Our proprietary microcellular plastic (MCP) offers dielectric constant (Dk) and dissipation factor (Df) for millimeter-wave-level high-frequency radio waves, resulting in a material that exhibits excellent radio-wave transmission properties. Therefore, it is expected to be applied to radomes of high-frequency antennas, such as base stations and antennas of 5G and in-vehicle millimeter-wave radars, which are required to realize high-speed communications.

In addition, this material reflects infrared rays well, and can suppress heat input from radiant heat from the outside.

If you are looking for materials for high frequency equipment, please feel free to contact us below.

5G Communication Issues and Requirements for Materials for Radome

Commercialized 5G communications have three features: high-speed, large-capacity, high-reliability, low-latency, and many concurrent connections. To achieve this, 28GHz band, which is the millimeter-wave band, was introduced in addition to 3.7GHz band and 4.5GHz band.

In Beyond 5G/6G, which is scheduled to be introduced in the future, a higher frequency band is expected to be adopted. While high-speed communication becomes possible when using high-frequency radio waves, the power consumption per telecommunications equipment is greater than before. In addition, when radio waves penetrate radomes or propagate through the air, they tend to be attenuated easily. For example, 5G radio waves in 28GHz band reach only about 100m distances. In order to expand the telecommunication area, base stations must be installed at these intervals. In addition, because of its straightness, there are many areas where radio waves do not reach due to obstacles, additional equipment such as repeaters are required.

In this way, as the performance of telecommunications equipment increases and the number of equipment increases, the power consumption associated with communications is expected to increase significantly. In response to this problem, telecommunications equipment such as antennas and sensors are required to transmit radio waves more efficiently, and materials with low dielectric and better radio wave permeability are suitable for radome that serves as the housing.

In 5G communication, many equipments are installed at short intervals. However, it is difficult to secure an installation location. One of the causes of this is that the equipment is heavy and the foundation to be supported cannot be secured. For this reason, lightweight materials are suitable for the radome of telecommunications equipment.

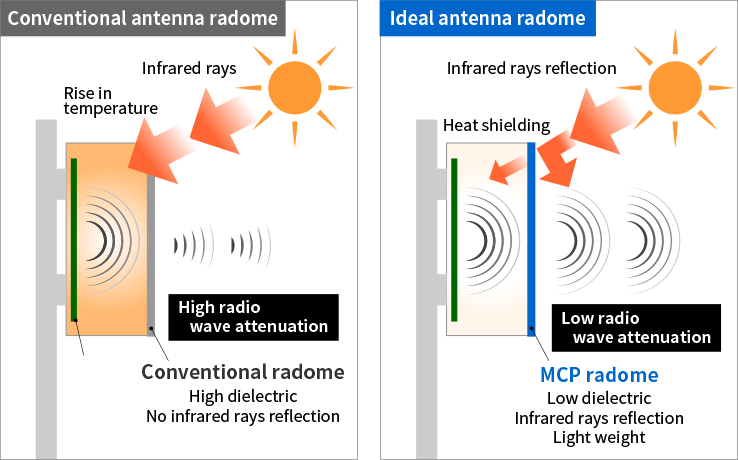

In addition, 5G communication equipment generates more heat than conventional equipment, which reduces the transmission rate. Especially when installed outdoors, the thermal design becomes more difficult because the temperature inside the equipment rises due to radiant heat when exposed to sunlight. For this reason, a material that reflects infrared rays and suppress the temperature rise caused by radiant heat is suitable for the radome of telecommunication equipment.

Low dielectric (improved radio wave permeability) and light weight by microcellular plastic (MCP)

1.Reduction of dielectric constant Dk and dissipation factor Df and weight reduction due to plastic foaming

To improve radio wave permeability, it is necessary to suppress reflectance at the material interface and attenuation due to dielectric loss during material permeability. And materials with lower dielectric constant Dk and dissipation factor Df are required. The lowest dielectric is vacuum, and since air also achieves nearly the same dielectric properties, bringing the material closer to the air improves radio wave permeability.

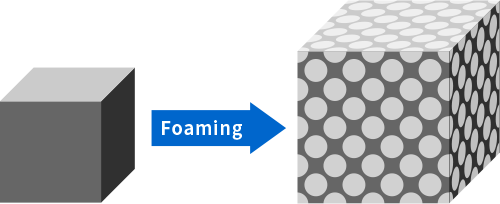

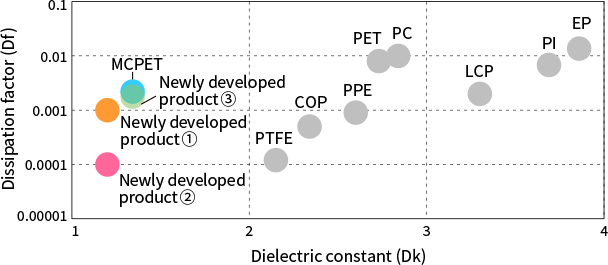

From this point of view, the relative dielectric constant Dk and dissipation factor Df of the material are lowered by expanding the inside of the plastic, which is relatively low dielectric, so that further improvement of radio wave permeability can be expected (Fig.1). Foaming also reduces the density of the material, resulting in a lightweight material.

2.Advantages of microcellular plastic (MCP)

Microcellular plastic (MCP) is Furukawa's unique technology.

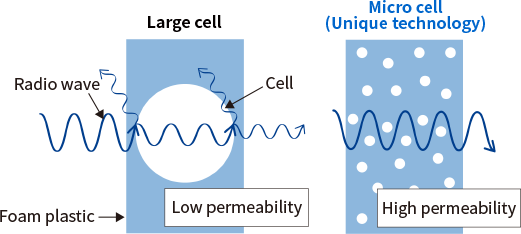

By foaming the plastic, the relative dielectric constant Dk and dissipation factor Df of the material can be reduced, resulting in excellent radio wave permeability. However, as the radio wave becomes higher frequency, the wavelength becomes shorter and approaches the cell size (submillimeter size) of the foamed material, so that it becomes more susceptible to the interface between the parent phase and the cell, thus impairing the radio wave permeability.

In response to this issue, by introducing our microcellular plastic (MCP), micron-sized cells can be formed, and good radio wave permeability can be obtained even for radio waves with high frequencies. Fig.2)

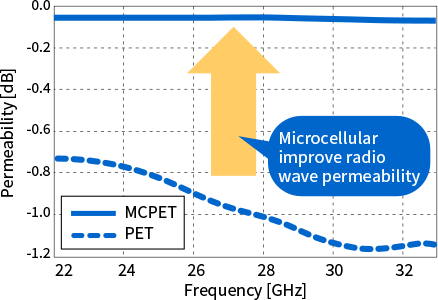

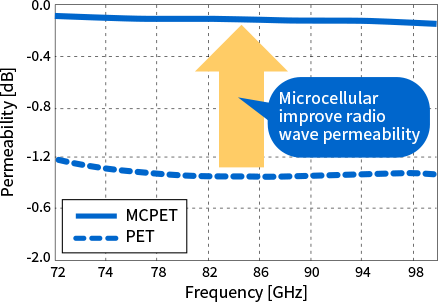

3.Radio wave permeability of microcellular PET (MCPET)

Fig. 3 and Fig. 4 shows the radio wave permeability of our microcellular PET (MCPET). Radio wave permeability have been greatly improved for non-foamed PET. It also exhibits almost constant radio wave permeability over a wide high frequency band of 22~100GHz.

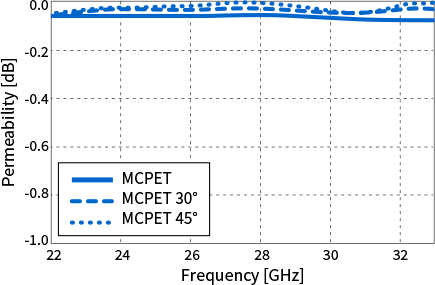

Fig. 5 shows the permeability of a sample when the incident angle of the radio wave is changed. Microcellular plastics (MCP) is a material that maintains high permeability even when radio waves enter at shallow angles, with little angular dependency.

(NOTE) Figures are examples of our tests.

(NOTE) Measured by the free space method (S-parameter method)

Infrared rays radiation reflected by microcellular plastic (MCP) (to suppress thermal rise caused by radiant heat)

1.Light reflectivity of microcellular plastic (MCP)

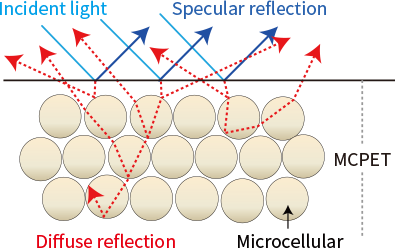

In the foam plastics, light is reflected at the interface between the resin and the cells. In our proprietary microcellular plastic (MCP), by making the cell diameter finer, light reflects repeatedly in the vicinity of the material surface. By suppressing the transmission of light into the material, this plastic exhibits excellent light reflectivity. Fig. 6

2. Infrared-reflective properties of microcellular PET (MCPET).

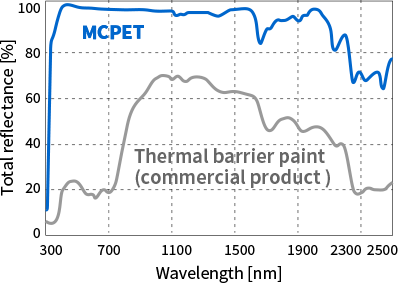

Fig.7 shows the light reflection characteristics of MCPET. This product has been adopted as a reflector for illumination for many years, and has high reflectance in the visible-light range (around 400~800nm), but has high reflectance even in the infrared region (>800nm).

(NOTE) Reflectivity is relative to aluminum oxide plate

3.Suppression of thermal rises by radiant heat due to microcellular PET (MCPET)

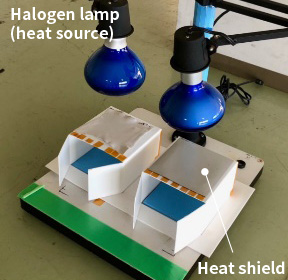

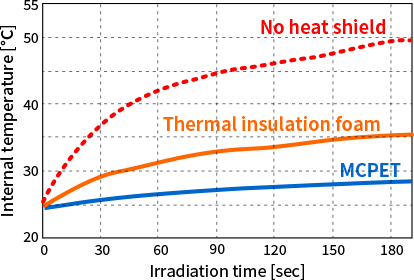

Our MCPET is highly reflective even in the infrared region and less affected by radiant heat. Therefore, it can be used as a heat shield. Fig. 8 shows the temperature change when the halogen lamp is applied. The temperature rise is suppressed by passing through MCPET.

Application of microcellular plastic (MCP) to radome for 5G communications equipment

From the above, Furukawa's unique microcellular plastic (MCP) has good radio wave permeability even in the high-frequency range of millimeter-wave bands and is light and highly reflective to infrared rays. By using this material in the radome of 5G telecommunication equipment, we can expect to improve the flexibility in installation spacing and installation location of telecommunication equipment, reduce power dissipation, and increase the flexibility in thermal designing.

Furukawa Electric can try to foam plastic materials other than the existing lineup according to the customer's requirements. In addition to dielectric constant Dk and dissipation factor Df, we will propose new foamed plastics based on our development capability of composition (blending) and foaming technology through experiments, if you inform us of various requirements such as flame resistance, heat resistance, thickness, density, etc.

Furukawa Electric has applied microcellular foaming technology to low-dielectric plastics (low dielectric constant Dk and low dissipation factor Df) to improve low dielectric properties and reduce weight.

Please click here to contact us.