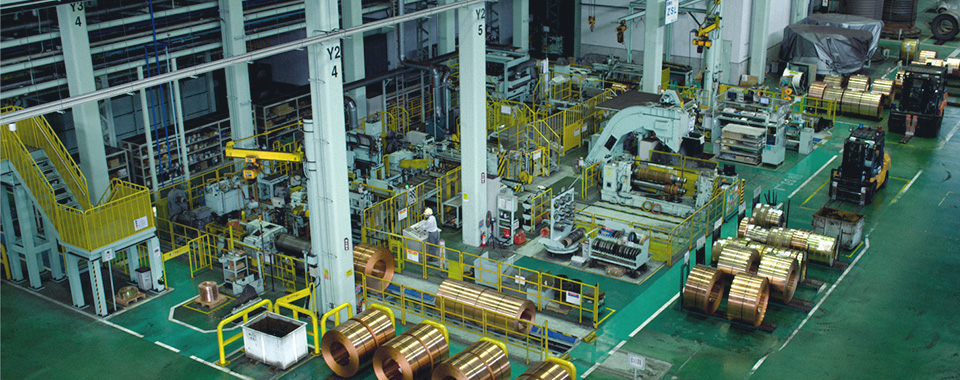

GOFC oxygen-free copper continues to evolve with a focus on 99.99% purity. Feedback from the customer has been the key to differentiation

Copper is a metal that is used in many areas of daily life but often goes unrecognized. It is essential for the electronic products we use every day, as well as for electric power and telecommunications infrastructure. High purity oxygen-free copper takes important roles in supporting higher performance electronic devices and high-volume telecommunications.

The GOFC oxygen-free copper manufactured by Furukawa Electric possesses high heat resistance not found in general-use oxygen-free copper. This feature was born in response to the issues faced by power semiconductor manufacturers and other customers who use GOFC. Let’s take a look at what led to the creation of GOFC, as well as a behind-the-scenes look at the subsequent improvements that have been made to GOFC and the efforts in terms of the environment.

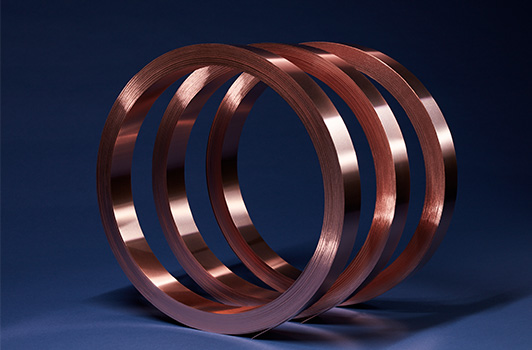

99.99% purity oxygen-free copper supports daily life in many unnoticed ways

Copper, the metal used in coins, is an excellent conductor of electricity compared to other metals, making it an essential material for electronic devices and components in electronic products. Although it often goes unnoticed, copper supports our daily life, including in connectors and power adaptor cords used in smartphones and computers and for the electrical wires in utility poles.

In recent years, following the advances in next-generation mobility and the clean energy technological revolution involving wind and solar power, the electrical and thermal burden on the power modules used to regulate electrical power is rapidly increasing. As a result, the power semiconductors installed in the power module need to have increased conductivity and reliability, and among the different grades of copper available, the highest purity “oxygen-free copper” is used.

Japanese Industrial Standards (JIS) classify copper with a purity of at least 99.96% as oxygen-free copper (C1020), but Furukawa Electric’s oxygen-free copper reduces oxygen impurities to 2ppm or less and exceeds the JIS requirement with a purity of 99.99%. Also, by manufacturing this oxygen-free copper in a shaft furnace, which has a high energy efficiency ratio, we will further contribute to reducing CO₂ emissions in the power semiconductor domain that is expected to grow globally in the future.

Behind the scenes look at the birth of the high heat resistant GOFC oxygen-free copper

In 2017, starting with oxygen-free copper (C1020), Furukawa Electric utilized the accumulated processing and heat treatment know-how to develop GOFC oxygen-free copper. The main feature of GOFC is its high heat resistance. The reason for pursuing this heat resistance was a desire to add the company’s strength to JIS oxygen-free copper, which had generally been viewed as “having no differentiating features”. By doing this, we wanted to create a product that would be chosen by customers.

To gain a better understanding of the needs for improved oxygen-free copper, we spent almost 1 year conducting hearings with various customers who use oxygen-free copper. From more than 200 VOC (Voice of Customer) gathered during this time, we recognized “heat resistance” is an issue in oxygen-free copper.

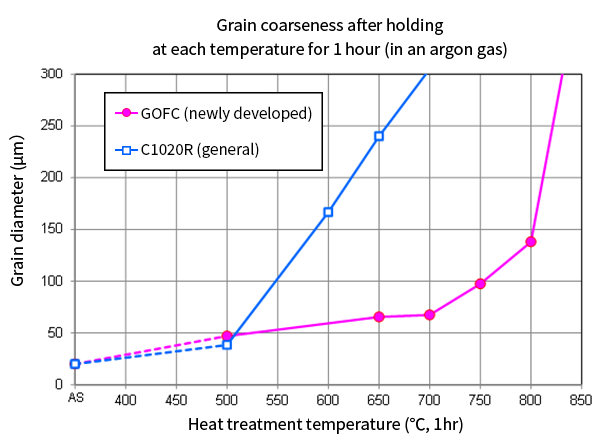

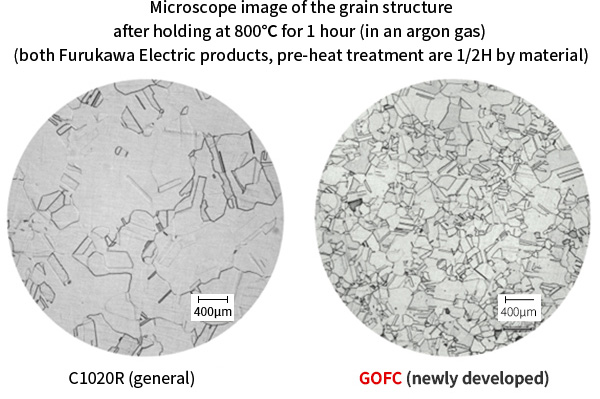

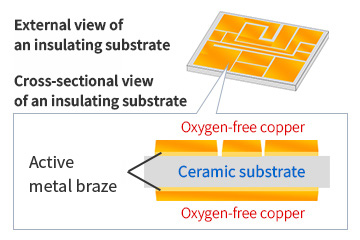

For the substrate used in power semiconductors, oxygen-free copper is brazed at high temperature to both sides of a ceramic board, but depending on the manufacturing process, the grain structure of the oxygen-free copper can become coursing. When general pure copper is “heated to temperature of around 500℃ or higher, the grain come together and the grain size bigger”. The same phenomenon occurs when the power semiconductor substrate is heat treated to 800℃.

This “large grain when heat treated at a high temperature” was the root cause of the customer issue learned through the VOC. When the grain becomes bigger, tiny roughness form on the surface of the material. These roughness reflect light irregularly, thereby impeding the inspection carried out by the customer using an optical camera to check for scratches. Many customers reported that this phenomenon caused inspection errors.

Of course, it is possible to increase detection sensitivity by adjusting the inspection device, but we decided that developing “oxygen-free copper without reflection”, or in other words “oxygen-free copper without grain growth when heated”, is the best approach for solving this issue faced by customers.

Development was extremely difficult because increasing heat resistance of oxygen-free copper is inversely related to increasing purity. However, one VOC indicated “even in the same oxygen-free copper, there are occasionally some lots without reflection”. Using this as a hint, we realized technology for intentionally creating “oxygen-free copper without reflection”. By applying our independently accumulated structure control technology and making innovations to the manufacturing process, we successfully developed GOFC, which realizes both high purity and heat resistance and does not reflection even after heat treatment at a high temperature.

When the newly developed GOFC was used for power semiconductor products, customers reported that “not only are there fewer inspection errors following heat treatment at a high temperature, but the semiconductor chip bonding failure rate also decreased”. Initially, it was not expected that along with increasing the inspection reliability for power modules, GOFC would also contribute to ensuring stable quality, so everyone involved in development was overjoyed to hear this feedback.

Listening to actual feedback from the customer and continuing to make improvements

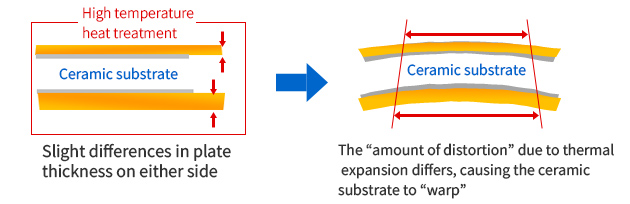

After developing GOFC that cleared the issue of heat resistance, a request was received to “minimize variation in GOFC thickness”. The issue faced by the customer was that when brazing oxygen-free copper to the ceramic substrate, the substrate would warp, which reduced the useful life of the product.

Because the coefficient of expansion of copper and the ceramic substrate are different, as the temperature changes when returning to room temperature after brazing the copper plate at a high temperature, the large contraction movement of the copper plate exerts tensile force on the ceramic board. When this occurs, if the copper plates attached to both sides of the board have inconsistent thickness, the differing forces acting on each side of the substrate cause it to warp.

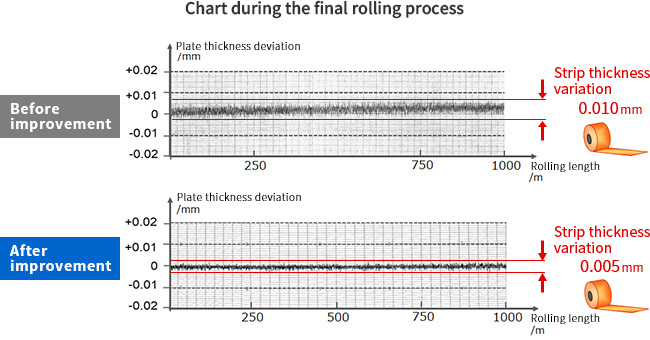

In response to this new issue, Furukawa Electric in 2022 increased strip thickness precision in the final rolling process that determines the thickness. We utilized thickness control technology accumulated in rollers for manufacturing lead frames (thin metal plates used for semiconductor packages), which are one of our strengths, to reduce GOFC strip thickness variation by 50% compared to previous product lots (for strip thicknesses of 0.25-2.0 mm).

Clean manufacturing from the upstream through the downstream processes. Contributing to reducing CO₂ emissions throughout the value chain

In this way, by developing and repeatedly improving GOFC based on customer input, we were able not only to increase manufacturing yield of power semiconductor products using GOFC, but we were also able to increase useful life of the power semiconductor and contribute to reducing CO₂ emissions from products that use these semiconductors.

In addition, we strive to show consideration for the environment from the first steps in the manufacturing process. Our GOFC manufacturing process uses 100% clean energy generated by Furukawa Nikko Power Generation from hydroelectric power.

In response to the recent growing demands for copper product recycling, we are aiming to establish a circular economy (recycling-based economy) with our customers and contribute to further reducing CO₂ emissions throughout the value chain (supply chain). We will continue to provide environmentally-friendly products and work with our customers to realize a carbon neutral society.

Share

Share Tweet

Tweet Share

Share