December 8, 2011

Furukawa Electric Co., Ltd. announces the release the S183PMII and S184PM-SLDF high-end fusion splicers, which provide appropriate conditions in fusion splicing of diversifying special fibers. These models incorporate substantially enhanced splice features achieved by software enhancement. Annual sales of 500 million yen are expected.

Background of Development

An external view of the fusion splicer

We have been offering high-end fusion splicers, the S183PMII and the S184PM-SLDF for speciality fiber and large diameter fiber, designed for research and development on and production lines of optical components.

In recent years, fiber lasers, fiber sensors, and other optical fiber-applied products are rapidly increasing. They differ from the field of conventional telecommunications in that it is more important to connect optical fibers of different forms (non-circular and holey), clad diameters, and core diameters in optimal condition. For popularly used optical fibers, splicing programs for optimal splicing are preset in fusion splicers. For processing any fiber without the preset programs as standard, it was necessary to create an optimal program or to make adjustments. In some cases, it was difficult for users to formulate optimal splicing programs and we provided support on a case-by-case basis. However, as fibers diversified and their types increased, growing needs emerged from users for easy splicing.

We have recently modified the software to achieve the automated creation of optimal splicing program according to the state and combination of fibers. We will continue to proceed with product development to answer the needs for speciality fiber splicing.

Product Features

Optimizing rotation adjustment for PANDA fibers

Widely used as polarization-maintaining fibers, PANDA fibers have different cross-section forms depending on the manufacturer and production lot. Generally, it is necessary to match the positions of the internal stress-applying members before the splicing process, but it was sometimes difficult to perform the process as their positions are not identifiable by observation from the lateral direction of the PANDA fiber. The new optimization feature creates a program for optimal rotation adjustment through automatic analysis of the PANDA fiber. This ensures easy splicing of PANDA fibers that are not supported as standard.

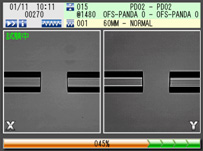

Screen for PANDA fiber rotation adjustment

Auto splice mode for joining different types of fibers

In the field of optical components, it is sometimes necessary to join optical fibers with different core diameters and to achieve low-loss splicings. Depending on the combination of fibers to be joined, this mode performs automatic discharge adjustment to achieve optimal low-loss connections.

Screen for the auto splice mode for joining different types of fibers

Intuitive manual fusion splicing

The manual splice mode has been fully revised to make it possible to achieve the intended splicing through simpler manual operation of the fibers. Equipped with tools for automatic core matching and automatic polarization plane matching, it ensures easy operation for switching between auto and manual modes. Providing a proper fiber data indication, it permits users to easily splice fibers while monitoring the fiber aligning status.

Note

For the S183PMII and the S184PM-SLDF already purchased, it is possible to add the new features by upgrading their software. The software upgrade is available for a charge.