November 29, 2012

On November 2, 2012, the Imaichi Plant and Higashi Plant of the Copper Foil Division, Metals Company obtained ISO/TS16949:2009 certification, an international quality management standard for the automotive industry. They are the first electrodeposited copper foil factories in Japan to obtain this certification.

Background

Furukawa Electric's electrodeposited copper foils for batteries are utilized by many customers as negative electrode power collectors for lithium ion batteries used for electric vehicles (EVs) and hybrid electric vehicles (HEVs). We have the largest market share in the world for electrodeposited copper foils for vehicle batteries. ISO/TS16949 is an international quality management standard for the automotive industry. It is based on ISO9001, with extremely strict requirements for meeting the global procurement standard for automotive parts. It emphasizes defect prevention and the reduction in variations and waste in the supply chain, customer satisfaction, and continuous improvement. Even compatibility with individual customer requirements is included as part of the review.

In recent years, many users worldwide have demanded that suppliers obtain certifications. The Copper Foil Division obtained this certification by strengthening its quality management and assurance system for further quality improvement and global expansion.

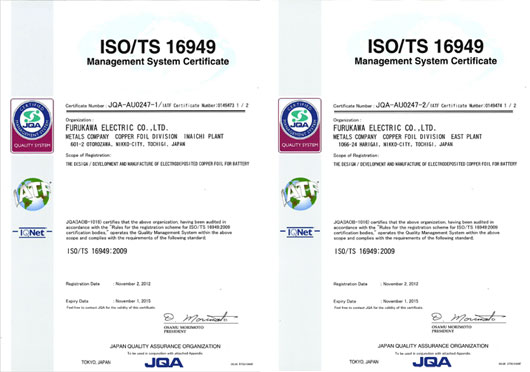

Details of certification and certificate of registration

| Standard: | ISO/TS16949:2009 |

| Scope of registration: | Design and manufacture of electrodeposited copper foils for batteries |

| Registered sites: | Imaichi Plant and Higashi Plant of the Copper Foil Division |

| Certification date: | November 2, 2012 |

| Certification body: | Japan Quality Assurance Organization (JQA) |