Global challenge as a group! Development of the revolutionary “Hollow Core Fiber (HCF)”

Today, optical fiber with a glass core supports telecommunications networks, but in order to achieve higher speeds and larger data volumes in next-generation telecommunications, the development of “Hollow Core Fiber”, which has a hollow core, is receiving increased attention. This article introduces the story behind the development of this Hollow Core Fiber and related cabling and connection technology.

Hollow Core Fiber is a completely new type of optical fiber

We use data communications in daily life, oftentimes without even knowing.

The volume of this data traffic, which is essential within society today, continues to increase, and in order to support that data traffic, R&D is being repeatedly conducted with the aim of “conveying more data at faster speeds”.

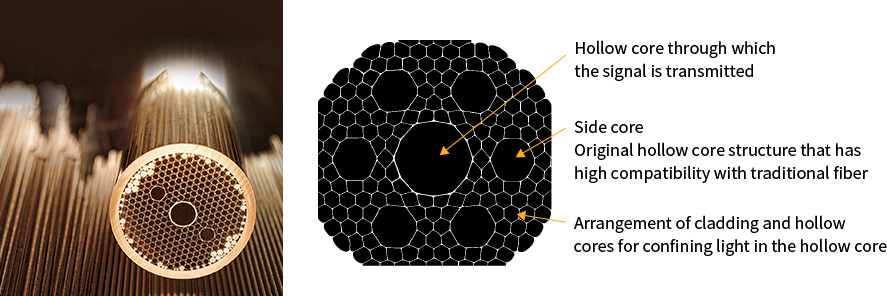

While progress is being made toward improving the optical fiber and cable, technological development is also being conducted toward fundamentally changing the structure of the optical fiber. This development is the Hollow Core Fiber. The internal structure has been fundamentally changed in order to fully utilize the intrinsic characteristics of light.

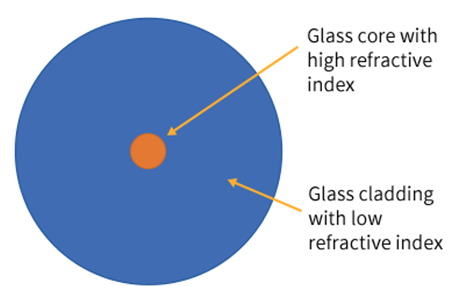

Compared to current optical fiber that uses two layers of glass with different refractive indexes, Hollow Core Fiber has a hollow core (air) that confines and transmits light based on a new principle. The structure of this Hollow Core Fiber has been studied for several decades, but it was difficult to achieve practical implementation due to a number of technical issues. Finally, “single mode” and “cabling, connectorization” were realized, and it was possible to move to the demonstration project phase.

Compared to optical fiber that uses a glass core with high refractive index to confine the light, Hollow Core Fiber is a revolutionary fiber that confines light in a core (hollow) with low refractive index. Using cladding to create a standard hollow core array structure, whereas light could only be confined in a core with high refractive index, the new fiber realizes a completely new principle of confining light in a hollow core with low refractive index. Also, utilizing an original hollow core structure called side core, it is possible to confine only the light necessary for transmission in the hollow core

Hollow Core Fiber has three major merits.

First, it reduces latency. With existing glass core fiber, latency of about 4.9 microseconds occurs for every 1km light is transmitted. This may seem like a small amount of time, but in a world competing to transmit data around the world in microseconds, such as supercomputers, as well as in the world of autonomous driving and remote medicine where transmission speed has a direct impact on life and death, these microsecond delays should be eliminated. Hollow Core Fiber has a latency of about 3.3 microseconds per kilometer, a reduction of about 30% compared to glass core fiber. The commercialization of Hollow Core Fiber is expected to play an important role in supporting the next-generation telecommunications environment.

The second merit is the “ability to withstand high power”. It is possible to input 1000 times more power compared to glass core fiber. Inputting too much power into a glass core fiber can damage the core or lead to the occurrence of “nonlinearity phenomenon” resulting from waveform disruption caused by deformation to the line form. However, in the case of Hollow Core Fiber, because the core is air, it is possible to input light at 1000 times higher energy density without damaging the core.

The third merit is “extremely low loss”. Because the core is air, it is possible to further decrease the loss of strength of the transmitted light.

The first two merits have reached the demonstration project phase, and although there are still many issues remaining in relation to the third merit of low loss, improvements are being made, with good results being achieved.

Hollow Core Fiber was selected to the “R&D Project for advanced optical communications technology that contributes to realizing a green society” of the Ministry of Internal Affairs and Communications in 2022, and research and development is being conducted in partnership with external institutions.

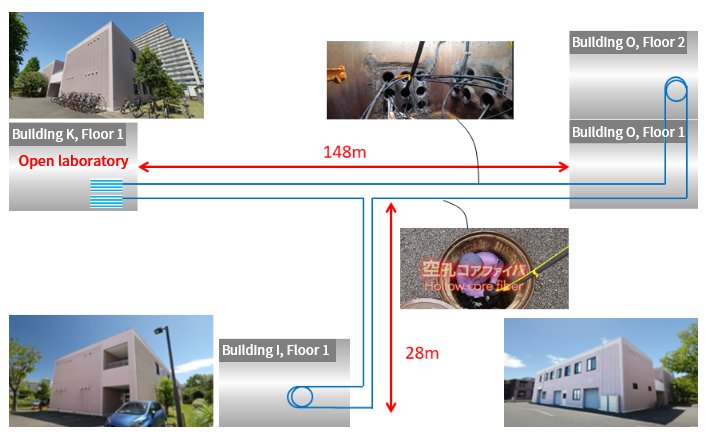

Also, Furukawa Electric partnered with Keio University in November 2023 to install Hollow Core Fiber in Keio Future Photonic Network Open Lab to create a network several hundred meters in length connecting multiple buildings. The laboratory is the world’s first open innovation laboratory where it is possible to use this new optical fiber in an environment similar to the real world.

* Excerpt: Keio University YouTube Channel “World’s First! Future Photonic Network Open Research Lab connected by Hollow Core Fiber” (Japanese only)

Making the ideal tangible. Hollow Core Fiber and cable was realized through cooperation with OFS and other members of the Furukawa Electric Group

Although Hollow Core Fiber has extremely appealing merits, the technological hurdles to realizing this fiber were very high. The group company OFS, which has research facilities in the United States, is playing a major role in the development aimed at commercializing this challenging fiber. Furukawa Electric worked tirelessly with OFS to develop the fiber, and while overcoming issues in relation to cabling and connection, it was possible to achieve the demonstration project level at which the fiber can be used in a near real world environment. As of today, only OFS and one other company in the world have realized technology for cabling Hollow Core Fiber.

Hollow Core Fibers are fabricated by an assemble and draw method, where custom drawn capillaries (glass tubes) are assembled orderly according to the design requested and placed inside an overclad tube. New fabrication methods were required in regard to ensuring performance and quality.

In addition, fabricating the fibers can be challenging, and there is a narrow regime for the fiber draw process such as draw speed, tension and accurate pressure control on the structure to obtain the design. In response, Furukawa Electric also worked with the Hungary-based group company FETI, which boasts advanced simulation technology.

Furukawa Electric, OFS and FETI collaborated on many projects, and based on strong mutual trust, we held online meetings once a month (either very early in the morning or late at night due to the time zone). In addition, there was a continuous exchange of information via email, and the members also met in person at larger group meetings when necessary. In this way, efforts have been made to maintain close communication between members of the group around the world.

The journey toward development of Hollow Core Fiber began at OFS in 2016 with the development of the fiber technology. This was followed by the development of cabling, efforts to fabricate longer lengths and the successful development of connectors that combine the Fitel splice on connector technology of Furukawa Electric. The first cable was installed in 2018 in Chicago, USA. Improvements have been made to the technology developed at that time, and demonstration projects are being repeatedly conducted.

The following is one story that occurred during a demonstration project. Normally, when installing cable, the fiber is cabled and connectorized at the factory before being delivered to the worksite. When the lab personnel attended the installation of the Hollow Core Fiber, it was a real eye opener to see the cable/connector assemblies processed and handled so carefully in the clean laboratory environment being handled very roughly by the installation teams pulling them through conduits. After seeing the installation worksite, the lab personnel felt even more appreciation for the cable designers who designed cable capable of withstanding such installation worksites and subsequent use.

Shown from the left are Brian Mangan, Gabe Puc, Tristan Kremp, Evan Dill and Benyuan Zhu

Breaking barriers through a combination of existing technology x novel concepts! Hollow Core Fiber connection technology

Connection technology is essential for the commercialization of optical fiber and cable. However, it was also a major hurdle that had to be overcome.

In the case of traditional glass core fiber, the technology for splicing the glass cores was already established. However, because the core of Hollow Core Fiber is hollow, it was necessary to develop a fundamentally different connection method. Also, following commercialization of Hollow Core Fiber, it will be impossible to convert the entire optical network to Hollow Core Fiber, so there needs to be technology for enabling compatibility with existing systems.

In response to this, the Fiber-optic Instruments Department in the Optical Fiber & Cable Products Division of Furukawa Electric started joint study and development with OFS.

Utilizing the knowledge of fusion splicer engineers, the team began development of new fusion splicing technology.

However, Hollow Core Fiber has a structure with many holes. Fibers are normally connected by applying heat to melt ends of each fiber and splicing them together, but in the case of Hollow Core Fiber, heat destroys the hollow structure. This challenge was solved by adding a novel approach to the existing fusion splicing technology. Because Hollow Core Fiber has a structure with many holes, given the difficulty in completely preventing damage to the structure, an original, optimized technology that takes into account damage to the structure was created. It took a year to develop this new connection technology, and although there are still issues that need to be resolved, the main issue was solved through an optimized method based a new concept.

After realizing fiber and cable connections, tests and assessments were conducted in cooperation with Keio University and The University of Electro-Communications, and the technology has received extremely high evaluations. In particular, upon presenting joint R&D conducted with students of The University of Electro-Communications, two awards were received from the IEICE Photonics Network Technical Committee. These awards were an opportunity to again recognize the attention this technology is receiving from outside the company and that it is already being held in high regard.

The development team expressed joy in their achievement, stating “We are relieved the solution worked as we hoped and are truly happy the technology has been so well regarded”

Challenges still remain to commercialization of Hollow Core Fiber

Cabling and connection technology have been established for Hollow Core Fiber. However, there are still issues that need to be resolved directed at commercialization. The evaluation results during the demonstration projects have still not reached the theoretical expectations, and it is necessary to further draw out the potential of this revolutionary fiber.

Going forward, it is also necessary to consider improving mass producibility, which is essential for realizing commercialization. With this aim, the fiber, connection and cabling technology need to be improved and optimized.

Because it is a new technology, while individually resolving the issues that arise, we will continue to work toward achieving future commercialization.

Share

Share Tweet

Tweet Share

Share