Functional ProductsProviding well-differentiated products through rapid response capabilities and flexible proposal capabilities

Made up of the AT & functional plastics, thermal management solution & products, memory disk and copper foil businesses, the segment manufactures and sells functional products through the processing of plastic and non-ferrous metals.

Business environment and background

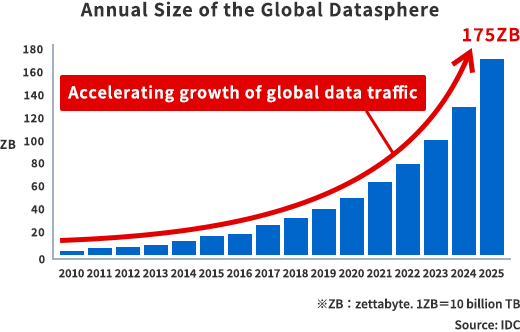

Ability to rapidly respond and make flexible proposals in response to growing data traffic and market changes will be key

Today, digitalization is occurring in many areas of society, and data traffic continues to grow every year following the shift to cloud services and introduction of 5G. As a result, along with increased performance of electronic devices such as smartphones and tablets, the data centers, base stations and other telecommunication infrastructure need to be strengthened, and products with higher performance are required.

In addition, the changes in data communications and social infrastructure markets are occurring at a dizzying pace.Manufacturers need to have the ability to rapidly respond to such changes and the ability to make detailed, flexible proposals.

Importance of high performance products is increasing for the realization of a sustainable society

Working to increase the use of renewable energy and ultimately achieve carbon neutrality, as well as to prevent and mitigate the increasing risk of natural disasters, are major social issues. Our desire to “realize a sustainable society” drives us to actively address these issues.

In our Functional Products business, we rapidly respond to customer needs and market changes through the use of our accumulated technology and capabilities of manufacturing. In addition, we provide environmentally-friendly products and high-performance products that assist disaster prevention and mitigation, and through this, we support the telecommunications and social infrastructure markets.

Business domains and strengths

Strategic use of the strong technology development capability and intellectual property

The Functional Products business of Furukawa Electric is made up of the AT & Functional Plastics, Thermal Management Solution & Products, Memory Disk and Copper Foil businesses. Each business boasts strong technology development capability for the product lineups, and at the same time, we strategically use our characteristic technology-related intellectual property.

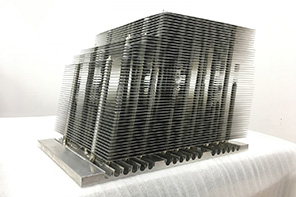

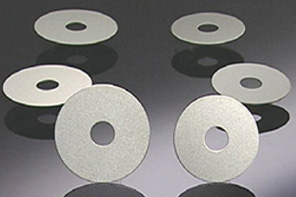

The AT business supplies tape for semiconductor process and adhesive film for semiconductors, and in response to the higher-speed, larger volume data communications, we have developed adhesive film with high thermal conductivity to solve the problem of semiconductor heat generation. The Thermal Management Solution & Products business provides cooling solutions to solve heat generation problems in Data Centers and telecommunication base stations. The Memory Disk business is working to increase HDD storage capacity by reducing disk thickness through the use of new alloys. The Copper Foil business provides copper foil for high frequency substrates that reduces data transmission loss in the high frequency range.

Broad, diverse product lineup backed by actual experience

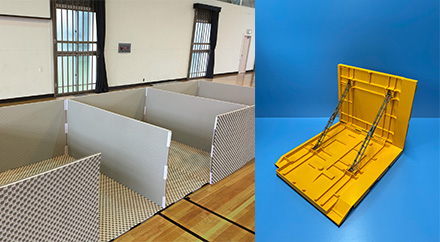

In the Functional Plastics business, the broad lineup of products utilizing foaming technology is also one of our major strengths. The lineup includes products for a wide range of applications, including pipe covers and roof backing that utilize the insulating properties, office supplies (flat files) and packaging materials that utilize the lightweight properties, disaster prevention mats that utilize the cushioning properties and light reflectors that utilize the reflective properties. The business boasts extensive and diverse sales experience based on the technological capabilities accumulated over the years.

Currently, active efforts are underway to develop next-generation display reflectors and next-generation substrates that utilize the radio wave transmittance and low-dielectric properties.

In recent years, we have enhanced our lineup of disaster prevention and mitigation products in response to the increasing severity of natural disasters linked to climate change. Also, following the accelerating decline in the number of construction workers, we are utilizing skill-free technology to provide cable conduit products that reduce onsite workload. In this way, we are contributing to the increased use of renewable energy and realization of next-generation social infrastructure without utility poles.

(Disaster prevention & mitigation)

(Reducing onsite workload and eliminating utility poles)

Medium-term business strategy (2025)

Securing a stable production system for tape for semiconductor process

Following the increased demand for semiconductors and more advanced processes, we have invested in continuing stable supply and increasing tape performance. A new factory is being built in the Mie Works, and it is planned to start mass production in 2025.

Contributing to next generation infrastructure through functional plastic products

In the functional plastics business, directed at further contributing to the disaster prevention and mitigation market, we are continuing our efforts to contribute to realizing next-generation infrastructure, including the provision of high performance troughs and systemized cable conduits and total route design solutions for underground, aboveground and incline installation locations. In addition, we are focusing on developing high performance products and creating new markets that apply our foaming technology.

Focusing on further differentiating and increasing the performance of each product

As the market demand for Data Centers and telecommunication base stations grows, we are working to further differentiate each of our products.

In the Thermal Management Solution & Products business, our focus is on developing high-performance cooling systems. The Data Center market is growing rapidly due to an increase in data traffic. In addition, Data Center projects that cater to the specific needs of the retail, medical, finance, media, and other industries are becoming more active, and the overall market is booming. As a result, our Thermal products are widely used to ensure cutting-edge semiconductors can perform at their full potential in Data Centers.

Also, in the Memory Disk business, we are aiming to further reduce the thickness of our products and increase the number of aluminum blanks installed in each HDD.

In the Copper Foil business, we have realized electrolytic copper foil with low environmental burden through the use of renewable energy and 100% recycled copper. We will focus on cultivating new domains and expanding the sale channels to new customers by developing next-generation copper foil for high frequency substrates that reduces transmission loss in the high frequency range and providing copper foil for electromagnetic wave shielding that has excellent machinability.

Products

Product website

Furukawa Electric Group, Vision 2030

Special site