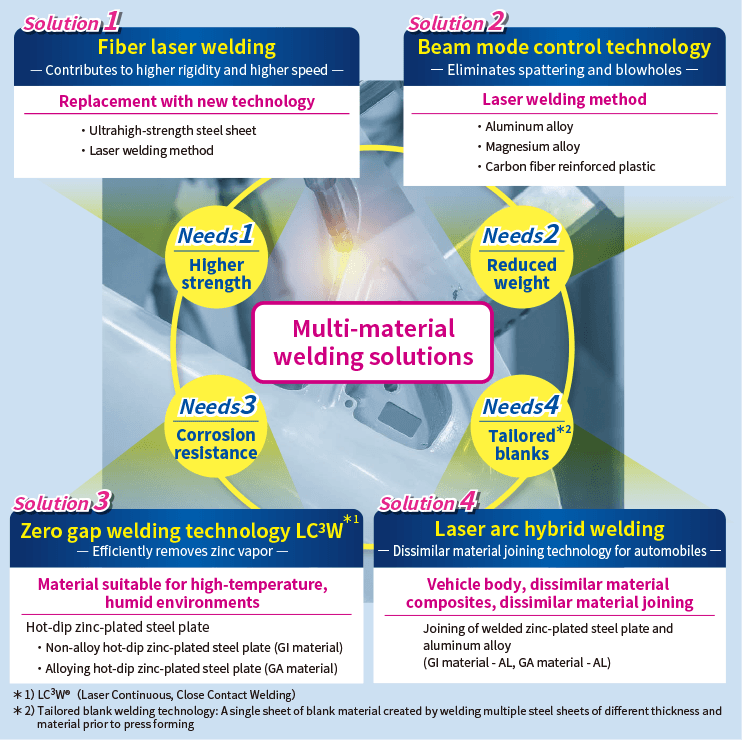

Furukawa Electric's laser welding solution for body materials

Stricter environmental and fuel efficiency regulations, and a growing need to reduce automobile weight has made it necessary to develop suitable processing technologies such as aluminum alloy welding and dissimilar material joining to meet these requirements.

In response to these unique customer needs, Furukawa Electric will contribute to tackling environmental issues such as global warming and the depletion of fossil fuels.

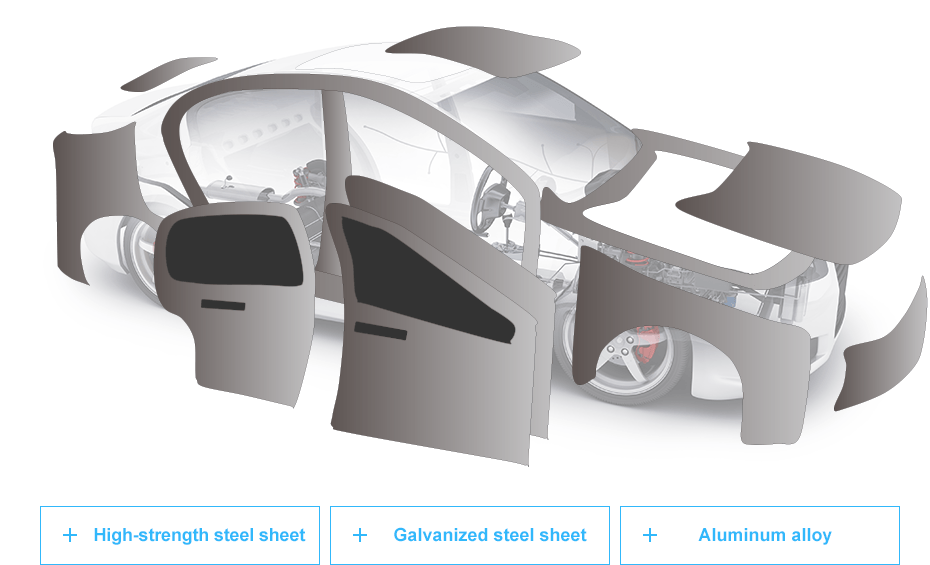

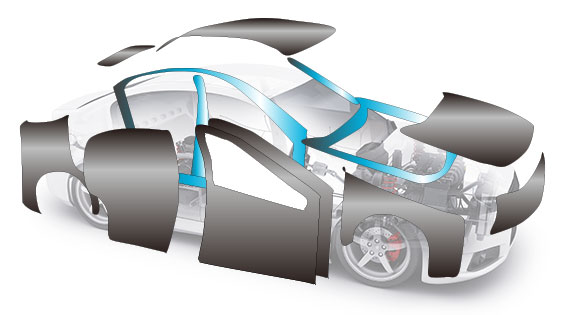

Examples of laser processing for body manufacturing

Click below for an introduction to application examples of laser processing to meet demands for improved strength and rigidity, as well as weight reduction for automobile bodies.

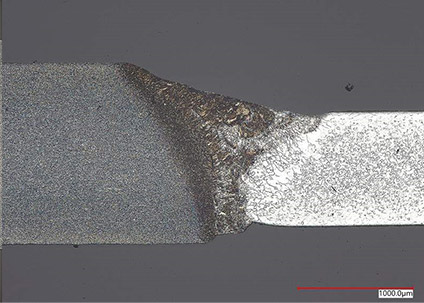

High-strength steel sheet (Tailored blanks)

Welding high-strength steel sheet of different sheet thickness. Significant suppression of spattering with beam mode control.

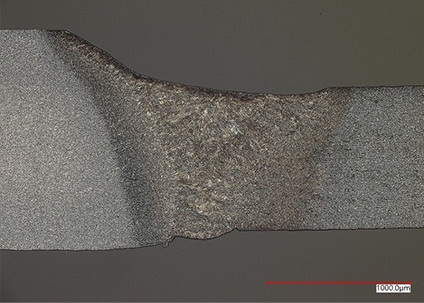

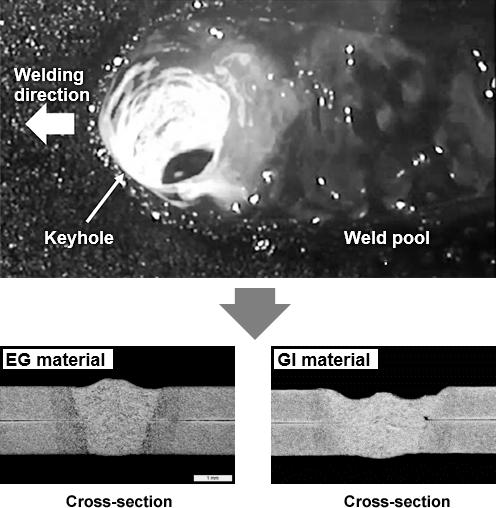

Galvanized steel sheet

Zero gap welding

LC3W ®(Laser Continuous, Close Contact Welding)

Dramatically reduces welding defects during welding of zinc-plated steel plate for automobiles.

(Note) EG material: Electrogalvanized sheet steel

(Note) GI material: Non-alloy hot-dip zinc-plated steel plate

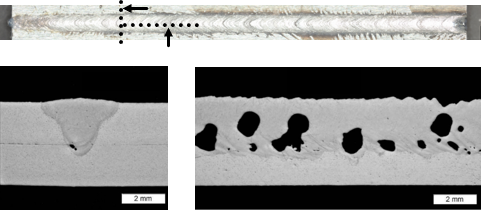

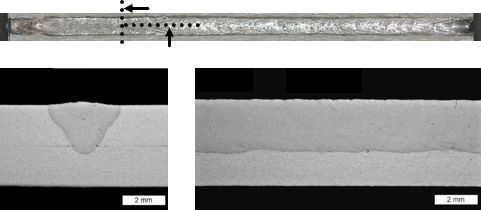

Aluminum alloy

Aluminum alloy welding

Dramatically reduces welding defects in aluminum alloys.

Without beam mode (Normal light condensing)

With beam mode control

Inquiries about Industrial Lasers