Feature 1High-quality, high-speed copper processing

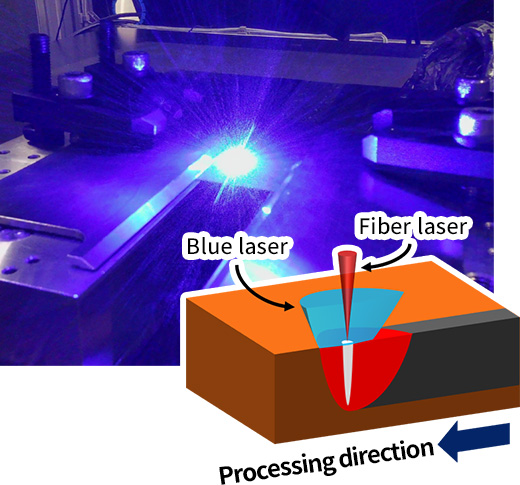

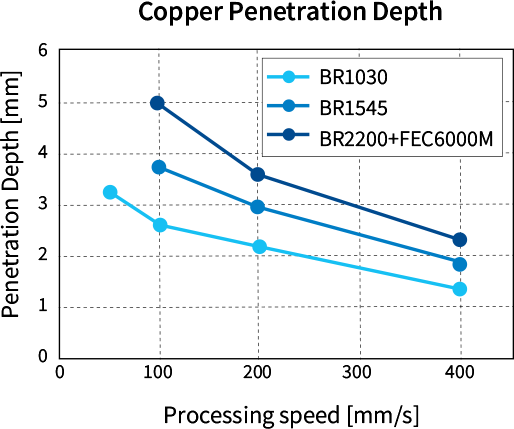

A Blue-IR hybrid laser that combines a fiber laser (IR) and a blue laser is used to perform deep copper penetration and high-quality welding that would be difficult to achieve using conventional lasers. The excellent welding stability of the blue beam allows for low-spatter and low-void welding of electrolytic tough pitch copper (ETP) prone to welding defects, as well as spatter-free welding of oxygen-free copper (OFC). The high-speed welding with a low thermal effect allows for crack-free copper welding of substrate materials that require high welding stability and low heat input, while the deep penetration allows for use with copper bus bars thicker than 3 mm, making it ideal for welding various copper components such as EV motors and inverters.

We handle a wide variety of copper products, and offer in-depth knowledge of copper materials. By working with our metal material R&D department to combine laser technology with material knowledge, we are able to offer our customers the best laser processing solutions.

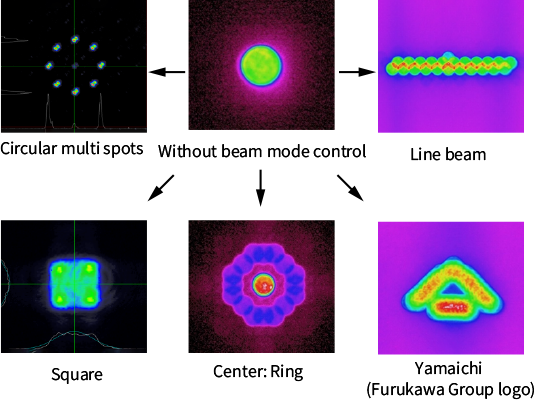

Feature 2Beam mode control technology (IR laser)

The key feature of our beam mode control technology is flexible mode design. The beam mode can be changed to the desired shape to obtain the optimum pattern and intensity distribution for each workpiece.

This is particularly effective for welding zinc-plated steel plates and aluminum alloys, which require precise heat input control.

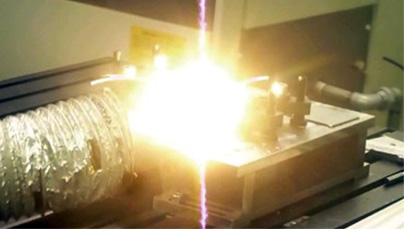

Spatter reduction with beam mode control

Spattering can be reduced using beam mode control technology, even under conditions in which spattering would normally occur.

In order to offer our customers the best possible processing quality, we also verify the effect of the improvements in processing quality obtained using beam mode control technology in our Application Lab.

Without beam mode control

a lot of spatter

With beam mode control

low spatter

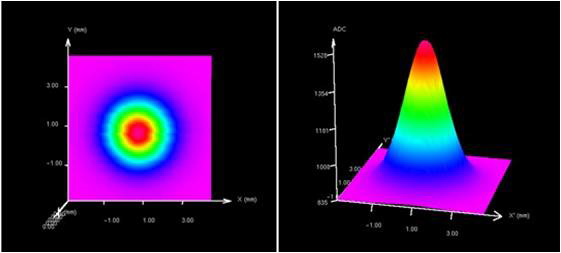

Feature 3World's highest-level beam quality

Both our IR and blue lasers have the world's highest-level beam quality. An extremely high beam energy density at the processing point allows for deep penetration and high-speed processing.

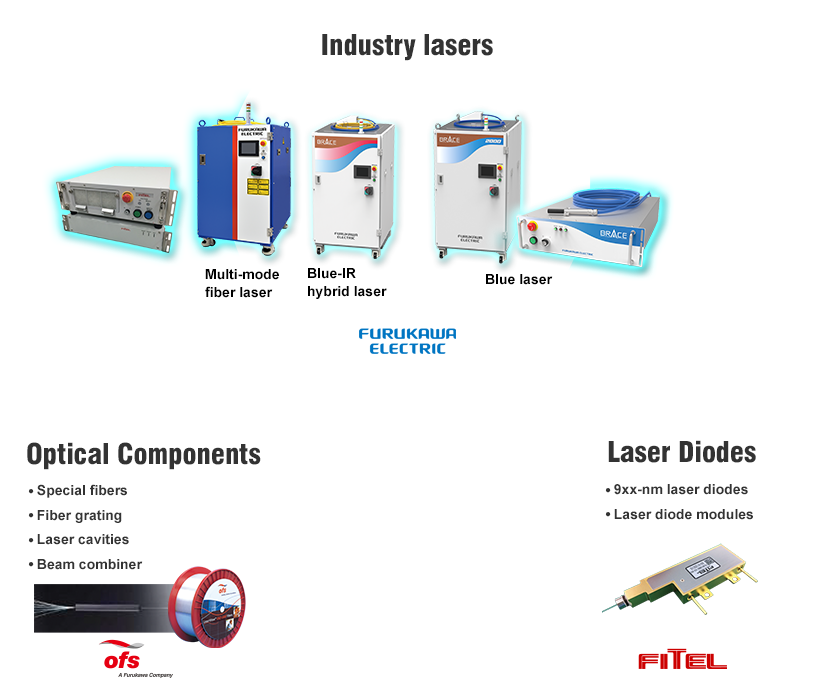

Made-in-Japan fiber laser incorporating Furukawa Electric technologies

High-power fiber lasers incorporating the communication technologies of Furukawa Electric, the first company in the world to practically apply optical fiber cable.

All of the core components are made by the Furukawa Electric Group, made in Japan fiber lasers with the superior level of quality.

Moreover, the fusion of Furukawa Electric’s technologies with our partner companies contribute to the realize world-class laser processing quality.

Furukawa Electric has a history of fiber lasers to meet the customer's needs of the times.

Furukawa Electric has incorporated a variety of new technologies (optical fiber, semiconductor lasers, optical fusion technology, etc.) cultivated through optical communications into its fiber lasers, and has been a Japanese pioneer in the field of fiber laser development.

Beginning with visible light lasers and low-power fiber lasers, in 2011, we began mass production of the first 300/500 W single-mode fiber laser in Japan.

Since then, we have continued to release new products including high-power fiber lasers and Blue-IR hybrid lasers.

In addition, we established the "Application Lab" to work with customers on solving problems and the "Customer Support Center" to enhance our support system, in an effort to align our activities with the needs of our customers.

We will continue to propose solutions that suit our customers.