- Blue-IR hybrid laser developed based on Furukawa Electric's extensive knowledge of copper characteristics

- Optimum Blue-IR hybrid laser examples

Blue-IR hybrid laser developed based on Furukawa Electric's extensive knowledge of copper characteristics

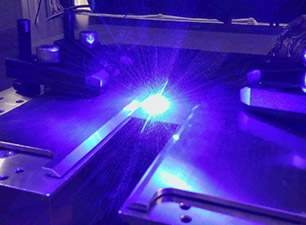

Furukawa Electric's Blue-IR hybrid laser is a hybrid laser by combination of a high-power blue oscillator equipped with a blue direct diode laser jointly developed with NICHIA CORPORATION and a near infrared (IR) fiber laser.

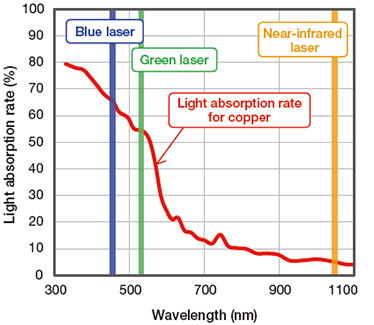

The following graph shows the light absorption rate of copper with respect to laser wavelength, with the horizontal axis representing the laser wavelength, and the vertical axis representing the light absorption rate of copper. When using a near infrared fiber laser on its own, the light absorption rate is approximately 4%, which requires the input of laser power with high energy density. However, this makes it difficult to achieve stable heat input, resulting in processing defects such as spattering and blowholes.

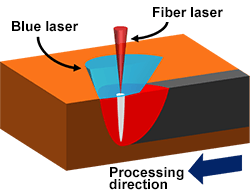

With newly developed Blue-IR hybrid laser technology, we have achieved the world's highest level of pure copper welding quality by using a blue laser, which has an excellent light absorption rate of 65% for copper, for preheating and a fiber laser for the main processing.

Processing principle using hybrid laser

Blue-IR hybrid laser application examples

The Blue-IR hybrid laser focuses on improving the quality of copper laser welding.

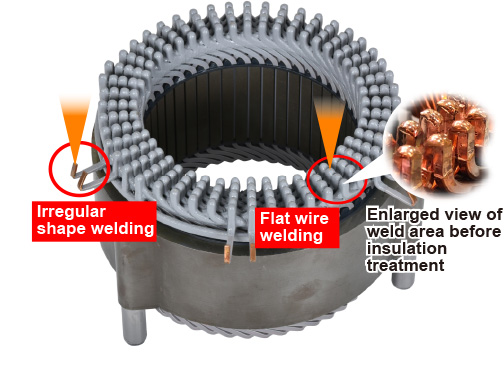

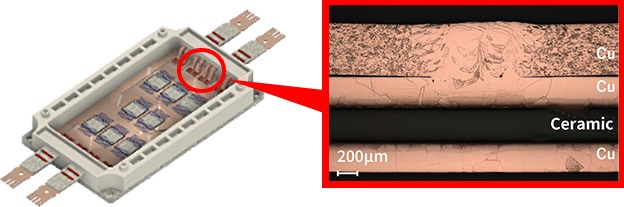

With the recent shift to EVs, demand for components such as inverters and motors is expected to increase in the future. Our Blue-IR hybrid lasers achieves the world's highest standards of welding quality, penetration depth, and processing speed in the manufacturing process of these parts, contributing to improved productivity.

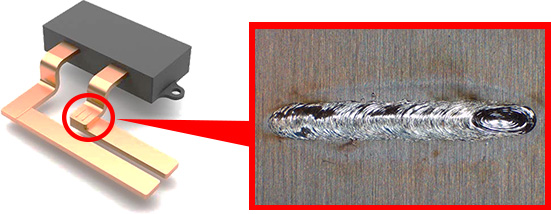

Application to bus bar connection area

Application to EV motor

Application to EV power module

Blue laser technology Blue laser and Blue-IR hybrid laser "BRACE®" product details

Inquiries about Industrial Lasers