Our lasers are capable of welding various materials (SUS, copper, aluminum, dissimilar materials, different thicknesses, etc.).

Blue-IR hybrid beam reduces spattering and blowhole formation during copper welding, and achieves a more uniform penetration depth.

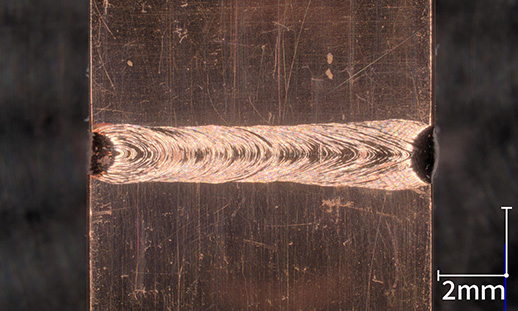

Copper lap welding

| Model | |

|---|---|

| Output | Blue laser 1 kW + Fiber laser (IR) 3 kW |

| Speed | 100mm/sec |

| Material |

C1020 t2mm 、t1mm |

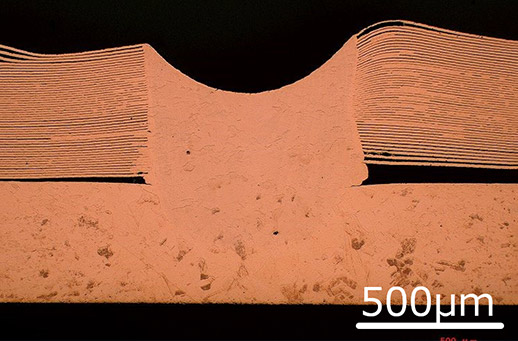

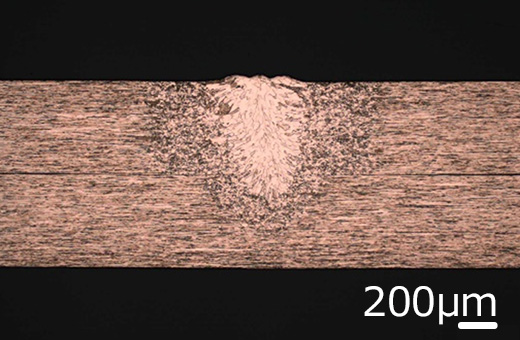

Copper foil + copper plate lap welding

| Model | |

|---|---|

| Output | Blue laser 150 W + Fiber laser (IR) 500 W |

| Speed | 5mm/sec |

| Material | Electrolytic copper foil t8 μm × 50 sheets, tab lead (copper plate) t0.5 mm |

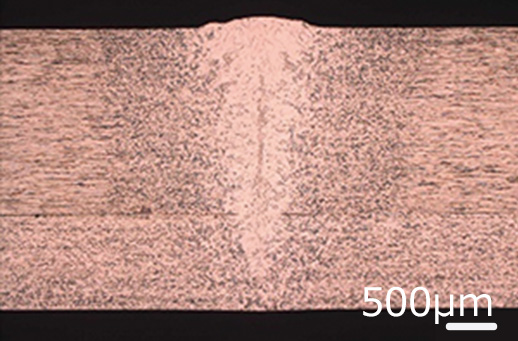

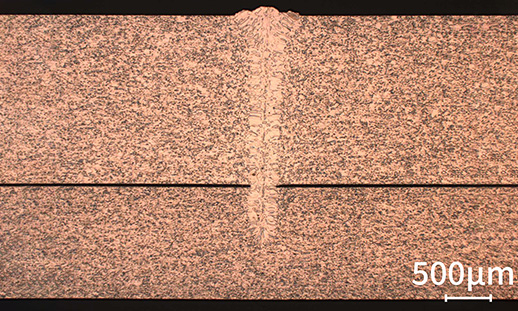

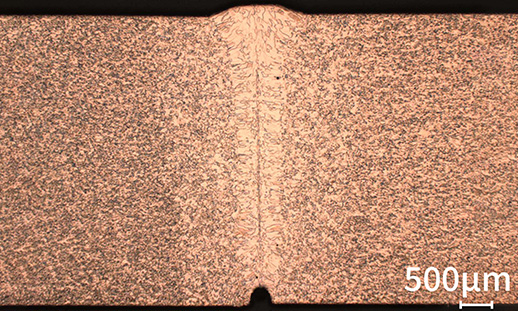

Copper bus bar lap welding (t=2mm / t=1mm)

| Model | |

|---|---|

| Output | Blue laser 1.5 kW + Fiber laser 4.5 kW |

| Speed | 150mm/sec |

| Material |

Oxygen-free copper (upper plate t = 2 mm, lower plate t = 1 mm) |

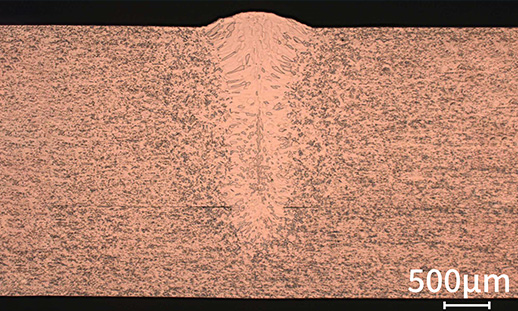

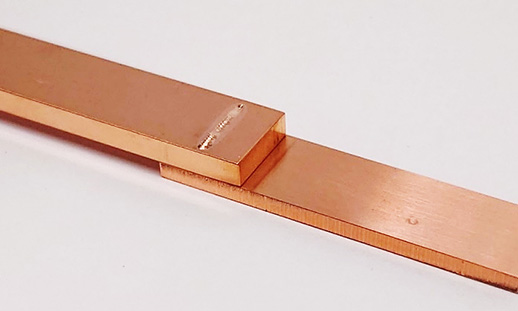

Copper bus bar lap welding (t3mm / t=2mm)

| Model | |

|---|---|

| Output | Blue laser 2 kW + Fiber laser 6 kW |

| Speed | 150mm/sec |

| Material | Oxygen-free copper (upper plate t = 3 mm, lower plate t = 2 mm) |

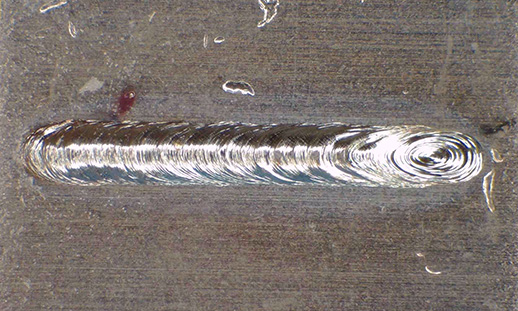

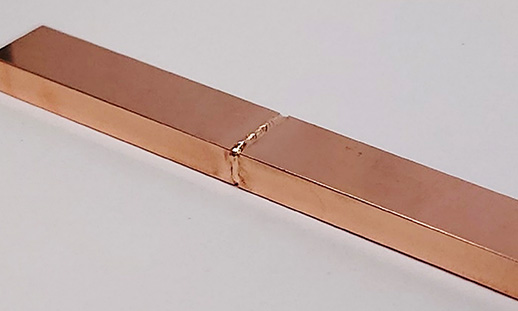

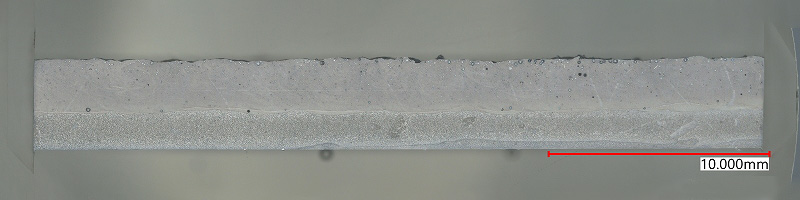

Copper bus bar butt welding (t5mm)

| Model | |

|---|---|

| Output | Blue laser 2 kW + Fiber laser 6 kW |

| Speed | 100mm/sec |

| Material |

Oxygen-free copper (t=5mm) |

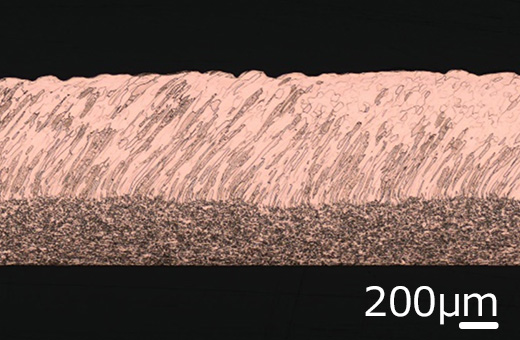

Copper plate lap welding

| Model | |

|---|---|

| Output | Blue laser 800 kW + Fiber laser 2200 kW |

| Speed | 450mm/sec |

| Material |

C1020 0.5mm x 0.5mm |

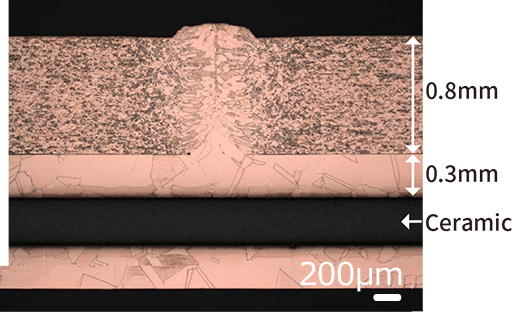

DCB substrate welding

| Model | |

|---|---|

| Output | Blue laser 1000 W + Fiber laser 1400 W |

| Speed | 400mm/sec |

| Material | C1020 0.8 mm x 0.3 mm overlapping With ceramic |

Aluminum die-cast welding

| Model | |

|---|---|

| Output | Fiber laser 6 kW |

| Speed | 100mm/s |

| Material | ADC12 2 mm x 2 mm overlapping |

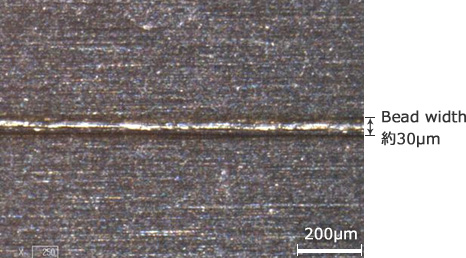

SUS304 lap welding

| Model | |

|---|---|

| Output | 150 W |

| Speed | 2500 mm/sec |

| Material | SUS304 t0.05 mm |

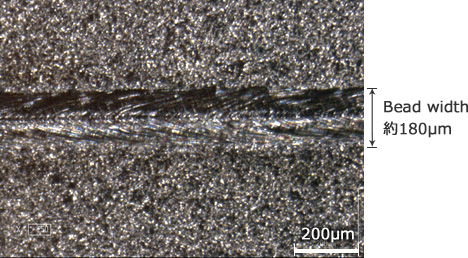

Titanium lap welding

| Model | |

|---|---|

| Output | 250 W |

| Speed | 400 mm/sec |

| Material | Pure titanium, t0.3 mm |

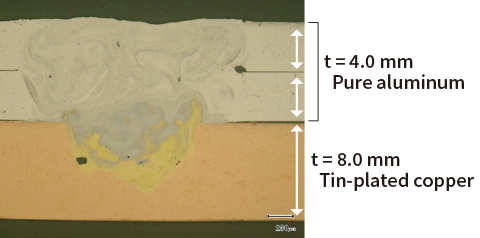

Aluminum (A5052), copper (C1100)

| Model | |

|---|---|

| Output | 300 W |

| Speed | 100 mm/sec |

| Material | Aluminum (A5052), copper (C1100) |

Monitoring device for high-precision in-process detection and quantification of contamination of protective glass for galvo scanning heads