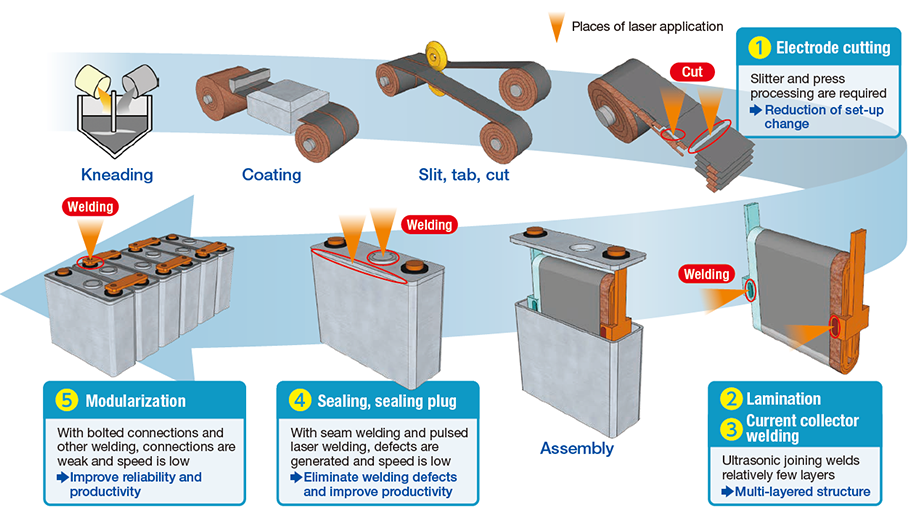

Furukawa Electric's laser processing solutions are able to quickly resolve issues in the lithium-ion battery manufacturing process, contributing significantly to productivity improvements and cost reductions.

Applications and benefits for manufacturing process

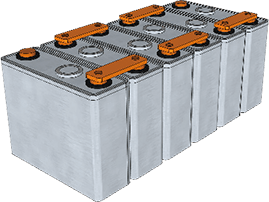

Square LiB manufacturing process

① Electrode cutting

| Technology and equipment | Ultra-fast modulated fiber laser (model No.: FEC1000S-7-SP) |

|---|---|

| Target material | Copper foil, aluminum foil, active material coated copper foil |

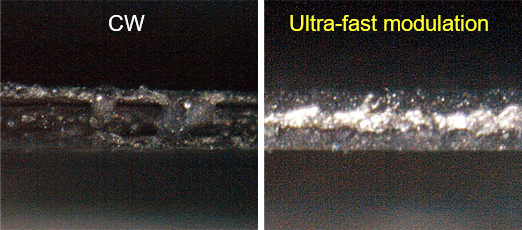

- Ultra-fast modulated fiber lasers can significantly reduce heat-affected zones on metal foil and active material layers, reducing the adhesion of metal lumps on end faces and metal foil surface exposure.

- High-speed, sharp cutting is possible regardless of the presence of active materials.

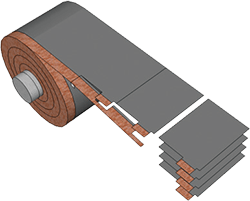

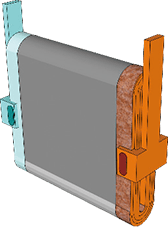

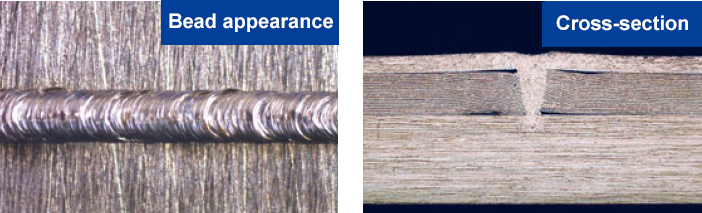

② Lamination ③ Current collector welding

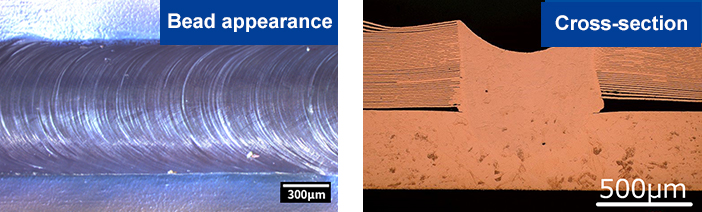

| Technology and equipment | [A] Blue-IR hybrid laser [B] Fiber laser (model No.: FEC1500S) + beam mode control |

|---|---|

| Target material | Laminated copper foil + tab lead (copper plate), welding possible for up to 50 sheets of copper foil |

- Stable heat input control is realized using the high optical absorption rate of blue laser for copper.

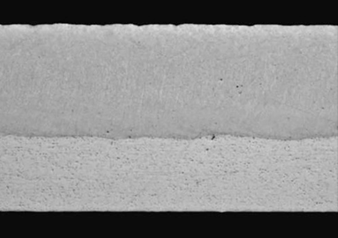

- High-quality lamination welding which suppresses spatter and blowhole formation when laminating 50 sheets of copper foil and welding copper plate has been realized.

- Processing with the Blue-IR hybrid laser realizes high-quality welding with virtually no welding defects on the surface of, or inside material.

- Combining a high-brightness fiber laser and beam profile control has made it possible to achieve both stability and penetration for the lamination welding of 50 sheets of copper foil.

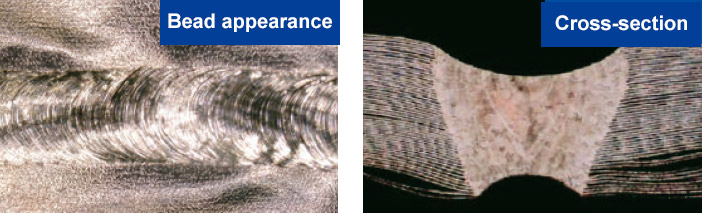

④ Sealing (aluminum)

| Technology and equipment | Ber laser (model No.: FEC4000M) + beam mode control |

|---|---|

| Target material | Aluminum package |

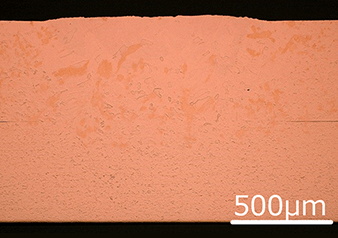

- Even for the lap welding of aluminum, which is considered prone to blowholes (cavities inside welded sections) due to its low melting point, stable welding is possible in combination with beam profile control.

⑤ Modularization

| Technology and equipment | Fiber laser (model No.: FEC1500S, etc.) + beam mode control |

|---|---|

| Target material | Copper bus bar, aluminum bus bar, copper-aluminum composite clad material |

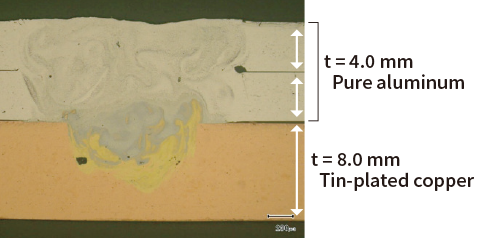

- High aspect ratio processing is realized with a high-brightness fiber laser.

- High-reliability welding is realized by processing with both high depth and high quality.

- Blowhole (cavities inside welded sections) formation is suppressed and high-reliability welding is realized even for the welding of the dissimilar materials aluminum and copper.

Inquiries about Industrial Lasers