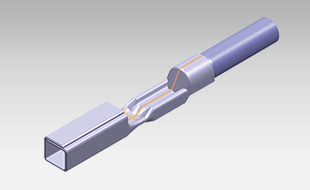

The corrosion-proof terminals for aluminum wire developed as a world-first at Furukawa Electric (α Terminal series) are a new kind of corrosion-proof terminal that seal the connection part with a tube structure to prevent corrosion. Individual corrosion-proofing processing is not required because a sealed structure is formed by crimping the tube shaped terminal to a wire. This realizes reductions in manufacturing costs and is contributing to the expansion of adoption of aluminum wires.

Click here for inquiries.