Agreement Reached with JUNG SHING WIRE CO., LTD. (Taiwan) to Collaborate in Highly Heat-Resistant Thin Rectangular Enameled Wire Business

- Manufacturing technology license granted with the aim of establishing de-facto standard -

Furukawa Electric Co., Ltd. and Furukawa Magnet Wire Co., Ltd. (“FMGW”) have agreed to grant a manufacturing technology license to JUNG SHING WIRE CO., LTD. (Taiwan) (“JSW”)(FMGW has a 21.15% stake in JSW) in relation to highly heat-resistant fine rectangular enameled wire (“Ribbon Wire”). The market for Ribbon Wire in inductor (coil) applications is rapidly expanding and the aim is for both companies to manufacture and sell Ribbon Wire using standardized global technology and quality to a common global standard.

Background

Along with increasingly miniaturized, flatter and more sophisticated models of smart phones and tablets, components have also become more miniaturized and there has been an increase in the use of low-back type components, components capable of handling high currents and highly heat-resistant components. The Ribbon Wire developed by Furukawa Electric Co., Ltd. and FMGW has gained an excellent reputation as a magnet wire for use in inductor applications, in which miniaturization has advanced remarkably.

The market for inductor components is expected to grow at more than 20% per annum at a global level along with the expansion in the electronic appliances market. There is a need to strengthen Ribbon Wire manufacturing capacity to meet the expansion of this market.

Characteristics of Ribbon Wire developed by Furukawa Electric

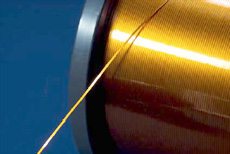

Ribbon Wire is a belt-shaped heat-resistant thin enameled wire with rectangular conductor dimensions. FMGW manufactures Ribbon Wire for different types of conductors (copper, aluminum, etc.) and the dimensions of Ribbon Wire and its conductor properties promote the miniaturization of coils and improve coil performance. Furukawa Electric Ribbon Wire allows uniform dimensions and highly heat-resistant insulation properties even on corner parts, which has been difficult to achieve using regular enamel manufacturing. Moreover, using Furukawa Electric Ribbon Wire improves the coil space factor in comparison to round wire, and contributes to miniaturization, the use of low-back type components and more advanced functions.

Details of Business Collaboration

Furukawa Electric and FMGW aim to build an increasingly cooperative relationship with JSW. Specifically, the aim is to achieve the following:

1) grant a license to JSW for ultra-fine size manufacturing technology, for which market needs are expanding; and

2) effectively utilize the manufacturing facilities and managerial resources of both companies to build a manufacturing system capable of responding to a future expansion in demand.

Furukawa Electric Group aims to supply customers around the world with Ribbon Wire products that are standardized and possess high quality and high reliability, and to establish the de facto standard in the field.

Share

Share Tweet

Tweet Share

Share