Received Order of Superconducting Cables from the International Thermonuclear Experimental Reactor (ITER)

- Contributing to the realization of the dream perpetual energy source -

Furukawa Electric Co., Ltd. has received an order from the Japan Atomic Energy Agency for some 30 tons of superconducting cables to be used in the International Thermonuclear Experimental Reactor (ITER) that is currently under construction in France.

The total value of the order-together with past ITER orders for superconducting cable-is about 2.5 billion yen. These superconducting cables are scheduled for delivery between February 2015 and October 2016.

Background

The ITER is an international megaproject designed to demonstrate the technical and scientific establishment of fusion energy through seven member entities: Japan, the European Union (EU), Russia, United States, Korea, China, and India.

In order to achieve nuclear fusion at the ITER, high-temperature plasma of more than 100 million degrees (Celsius) is confined in a strong magnetic field, and using the changes in the strong magnetic field, it is necessary to generate large current in the plasma. Japan is in charge of producing the Nb3Sn(note 1) superconductor using seven central solenoid coils (one is a spare coil) that generate the varying magnetic field, and counting the order this time, Furukawa Electric will produce superconducting cables for two of these coils.

Overview

Although the record breaking heavy snow in February of this year damaged part of the Furukawa Electric superconducting plant in Nikko, it is able to produce superconducting cables for ITER by proceeding with intensive recovery. At the Nikko Copper Plant, Furukawa Electric produces Class 1 oxygen-free copper (note 2) that satisfies the Residual Resistance Ratio (RRR) (note 3) requirement of >350 for stabilizing material used in superconducting, and has integrated production combining superconducting material in superconducting cables. In addition, all steps are taken as clean electricity through hydropower, achieving CO2 emissions of 50% or less than plants of the same scale at competing companies.

In this way, the superconducting cables are twisted by Furukawa Electric Group Company, Furukawa Electric Industrial Cable Co., Ltd (headquarters: Arakawa, Tokyo; President: Yoshitaka Hattori), and VISCAS Corporation (headquarters: Shinagawa, Tokyo; President: Susumu Sakuma). Although the process is long and complex-from raw materials to twisting the cables, and with the continued impact of the damage from the snow-the collective strength that the Group has shown has led to orders.

Furukawa Electric has also industrialized low temperature (metal) and high temperature (oxide) superconducting material, and a wide range of products. Low temperature superconducting still accounts for a great deal of the weight in megaprojects such as the ITER, and in commercial applications such as the MRI and NMR. Areas that call for high magnetic fields, however, need both low and high temperature superconducting, and Furukawa Electric is the only manufacturer that can provide hybridized solutions with low and high temperatures. Product Features and Data Specifications

Product Features and Data Specifications

- Featuring the best critical current density (note 4) in the world, at a very low temperature of 4.2K, in a high magnetic field of 12T, with copper/tin alloy as the base material in producing Nb3Sn superconducting cable.

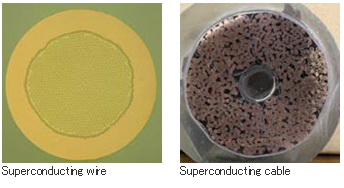

- The superconducting cable is made of 576 superconducting wires with a diameter of 0.83 mm twisted together with 288 copper wires of the same size, finishing with an outer diameter of about 34 mm. In a common test evaluating the electrical current performance, the cable achieved the best current sharing temperature (Tcs) (note 5) in the world, at 7.4K (45.1kA, 10.85T).

Glossary

(Note 1)Nb3Sn:

The intermetallic compounds of niobium-titanium alloy (NbTi) and triniobium-tin (Nb3Sn) are incorporated in the superconducting material. Generating a magnetic field in excess of ten Tesla (10T) at liquid helium temperature (4.2K) calls for Nb3Sn (Hc2=24T), which has a high critical magnetic field where superconductivity is lost. Nb3Sn superconducting material is used in the ITER-CS that operates in a 13T magnetic field.

(Note 2)Class 1 Oxygen Free Copper:

Oxygen free copper is used in electron tubes such as transceiver vacuum tubes, microwave tubes, and the like. Oxygen free copper is especially needed for items which high electric field is applied to and which are used in an ultra-high vacuum. The crystal grains size of the oxygen copper is strictly regulated and the oxygen content is specified less than 10 parts per million (ppm).

(Note 3)Residual Resistance Ratio (RRR):

RRR is material property and calculated from following formula: resistivity at room temperature divided by the very low temperature at 4.2 K. A high RRR (low residual resistance) is needed in the stabilizing material for superconducting.

(Note 4)Critical Current Density (Jc):

This is the current density limit (maximum current density) where superconductivity flows without fail under a constant temperature and magnetic field. For Nb3Sn wire, this is defined as the current value per unit area for the portions other than the stabilized copper.

(Note 5)Current Sharing Temperature (Tcs):

This is the temperature limit (maximum temperature) for rated current to flow under a constant magnetic field. Because heat is generated in the conductor itself in addition to the heat inflow from outside in a superconducting conductor, an ample Tcs margin is needed as a design temperature for stable operation.

About Furukawa Electric Group

Furukawa Electric (TSE; 5801, ISIN; JP3827200001) Group started business in 1884, when its copper-smelting facility and wire manufacturing factory was established. Since then Furukawa Electric has become pioneers in the latest technologies by addressing diverse technological issues. Furukawa Electric has released products in a number of areas, including telecommunications, electronics, automobiles, and construction, with the three types of materials it works with at their core, namely, optics, plastics, and metals. Many of these products have attained the top global market share, and all of its products have contributed to society in numerous business areas. Furukawa Electric reported consolidated revenues of JPY 931.8 billion (approximately USD 9.3B) for the fiscal year ended March 31, 2014.

Share

Share Tweet

Tweet Share

Share