Furukawa Electric Co., Ltd. to Enter Full-Scale Development of Copper Strip Product and Fiber Laser Solutions

-Strong and stable copper laser welding now a reality -

Furukawa Electric has committed to the full-scale development of copper strip product and high power fiber laser solutions. Strong and stable copper laser welding will help to electrify and bring vehicles equipped with on-board batteries to the next level.

Background

Furukawa Electric’s high power fiber lasers use a unique fiber structure and beam combination technology to deliver powerful resistance to reflected light and advanced light-harvesting performance. Research toward applying this technology to processing metals with high reflectivity that are said to be difficult to join (such as copper and aluminum) continues along with efforts to bring the technology to practical use.

Welding defects such as spattering(note 1) and blowholes(note 2) easily occur when laser welding copper. This is seen by manufacturers of parts related to on-board batteries and motors as a major technical hurdle to resolve.

Content

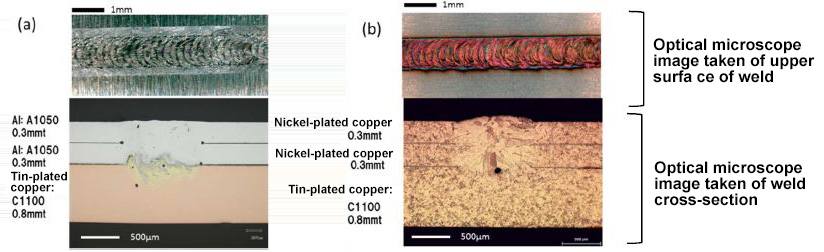

Furukawa Electric will begin full-scale development of solutions that combine high power fiber lasers with copper alloys optimized for laser welding. Furukawa Electric has developed a new fusion technology that minimizes spattering and makes it possible to weld with stable bead formation(note 3), by combining high power fiber lasers with copper alloys featuring optimized characteristics such as new material compositions, texture control, and plating thickness.

(note 1)Spattering: Microparticles that scatter from fused metal when laser welding. They can cause welding defects and have a negative impact on quality.

(note 2)Blowhole: A type of welding defect that occurs in the weld area. It takes the shape of a round cavity within the welded metal.

(note 3)Bead formation: Metal that is melted then solidifies during laser welding.

Furukawa Electric continues to monitor and verify welding defects and other information. Interested parties are invited to try the technology at the Chiba Works Application Laboratory, along with this copper strip technology and fiber laser processing technology.

About Furukawa Electric Group

Furukawa Electric (TSE; 5801, ISIN; JP3827200001) Group started business in 1884, when its copper-smelting facility and wire manufacturing factory was established. Since then Furukawa Electric has become pioneers in the latest technologies by addressing diverse technological issues. Furukawa Electric has released products in a number of areas, including telecommunications, electronics, automobiles, and construction, with the three types of materials it works with at their core, namely, optics, plastics, and metals. Many of these products have attained the top global market share, and all of its products have contributed to society in numerous business areas. Furukawa Electric reported consolidated revenues of JPY 843.3 billion (approximately USD 7.8B) for the fiscal year ended March 31, 2017.

Share

Share Tweet

Tweet Share

Share