Furukawa Electric Develops New A/C Duct Insulation Material to Help Improve Construction Site Environments and Reduce Construction Times

- First in Japan to use non-combustible resin foam type insulation -

Furukawa Electric Co., Ltd. has successfully developed "Duct Insulation Ace," a new non-combustible resin foam type insulation material with reinforced aluminum, for use as insulation material for A/C ducts. The product, which was developed to improve environments during A/C duct construction and reduce construction time, will enter full-scale mass production during the first half of the 2017 FY.

Background

A/C ducts are a type of piping mainly used to create airflow for A/C, ventilation, smoke exhaust, and the like in condominiums, hotels, office buildings, and large shopping malls. They are indispensable pieces of architectural equipment for maintaining comfortable living environments.

A/C ducts are generally built by first installing the ducts, and then installing inorganic fiber type insulation material to retain heat. However, this material can be problematic as its insulation performance can deteriorate due to moisture absorption, the construction environment could worsen as fibers are released, and there is a shortage of workers specialized in heat retention work. It is also difficult to attach insulation material to the bolts and fastening clips used to connect ducts. This can easily result in internal condensation, and as this condensation is absorbed, the weight could cause the insulation material to drop off.

Content

Furukawa Electric is the first in Japan to successfully develop "Duct Insulation Ace," a new non-combustible resin foam type insulation material with reinforced aluminum, for use in A/C ducts.

This product uses an independently developed non-combustible resin foam type insulation material rather than conventional inorganic fiber. In addition to preventing fibers from being released into the environment when installing A/C ducts, it also offers simplified workability and adhesion, as well as scratch resistance. This allows heat retention processing to be performed during the duct manufacturing process, considerably reducing time spent conducting heat retention measures at the construction site. The product has already been selected for use in lodging facility projects in which major subcontractors will participate. Full-scale mass production will begin during the first half of the 2017 FY.

Although demand for construction will increase leading up to the 2020 Tokyo Olympics, there are concerns over labor shortages. Toward that end, Furukawa Electric will continue to play an active role in developing products in order to expand the lineup of "Duct Insulation Ace" products and help reduce labor.

Features

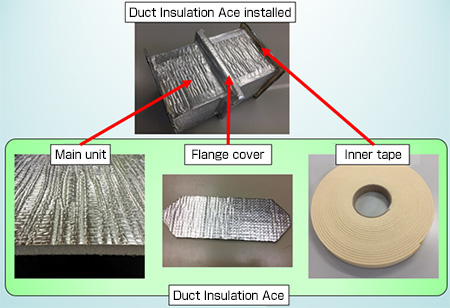

"Duct Insulation Ace" consists of three parts: the main unit cover that insulates the duct unit, the flange cover that insulates the flange, and the inner tape.

The main unit cover and the flange cover feature a laminate structure that uses newly developed non-combustible resin foam and highly durable aluminum foil to offer heat retention and durability, while the surface that attaches to the duct is processed with adhesive. This makes it difficult to scratch, yet simple to work and apply. The inner tape uses proprietary technology to offer increased flexibility and high following characteristics to prevent internal condensation in the uneven surfaces of the flange.

"Duct Insulation Ace" is currently under application for certification as a non-combustible material by the Minister of Land, Infrastructure, Transport and Tourism according to Japanese laws and regulations, and is expected to be certified shortly.

About Furukawa Electric Group

Furukawa Electric (TSE; 5801, ISIN; JP3827200001) Group started business in 1884, when its copper-smelting facility and wire manufacturing factory was established. Since then Furukawa Electric has become pioneers in the latest technologies by addressing diverse technological issues. Furukawa Electric has released products in a number of areas, including telecommunications, electronics, automobiles, and construction, with the three types of materials it works with at their core, namely, optics, plastics, and metals. Many of these products have attained the top global market share, and all of its products have contributed to society in numerous business areas. Furukawa Electric reported consolidated revenues of JPY 874.9 billion (approximately USD 8.0B) for the fiscal year ended March 31, 2016.

Share

Share Tweet

Tweet Share

Share