Sales Launched for a New Power Semi-conductor Cooling Device

Since the 1980s, Furukawa Electric has sold POWER KICKER, a heat pipe-based cooling device for the power semi-conductors found in inverters used for railway drives, solar power generation, and other such equipment. The railway vehicle and solar power generation markets, however, are expected to see more robust demand for these devices as a result of the strong appetite for investment stemming primarily from developing economies and trends in ecology.

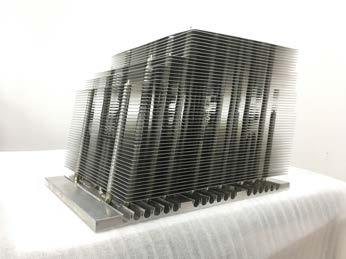

In response, Furukawa Electric began selling a new model in October 2018. In place of conventional solder joints, the thermal bonds that connect the heat-receiving member(note 1) that accepts the heat from the power semi-conductor and the heat conducting(note 1) heat pipes are made using a newly developed joining technology that is free of environment-affecting substances.

(note 1)Heat-receiving member

A member that primarily takes the form of an aluminum block, and that consists of a mechanism (screw) to attach the power semi-conductor and grooves into which the heat pipes are embedded.

(note 2)Heat conducting member

The heat conducting heat pipes are shaped into their uniquely designed forms and thermally joined to the heat-receiving member that receives the heat from the power semi-conductor. The heat conducting member conveys this heat to the cooling fin side.

Background

Although conventional solder joints offer an excellent balance between heat transfer performance and strength, they present challenges in terms of environmental harmony and cost, so Furukawa Electric undertook the development of an alternative technology. In this way, we developed a rivet joint technology and utilized a specialized design that relies entirely on the heat-receiving member and the heat pipes. This approach also aims to enable efficiency improvements on the cooling fin side and realizes greater environmental harmony, lower costs, and lighter weights while maintaining the overall performance of the cooling device.

Details

- Developed a specialized rivet joint design that is free of environment-affecting substances and that relies entirely on the heat-receiving member and the heat pipes

- Did away with solder joints, thereby eliminating the need for solder and heat-receiving member surface treatments, and helping to reduce weights

- Improved the efficiency of cooling fin installation

- Target sales value: 5 - 700 million yen/year

About Furukawa Electric Group

Furukawa Electric (TSE; 5801, ISIN; JP3827200001) Group started business in 1884, when its copper-smelting facility and wire manufacturing factory was established. Since then Furukawa Electric has become pioneers in the latest technologies by addressing diverse technological issues. Furukawa Electric has released products in a number of areas, including telecommunications, electronics, automobiles, and construction, with the three types of materials it works with at their core, namely, optics, plastics, and metals. Many of these products have attained the top global market share, and all of its products have contributed to society in numerous business areas. Furukawa Electric reported consolidated revenues of JPY 967.3 billion (approximately USD 8.7B) for the fiscal year ended March 31, 2018.

Share

Share Tweet

Tweet Share

Share