Realizing Higher Quality Welding in Aluminum Materials Used for Automobiles

- Contributing to Making Automobile Bodies Lighter and Improving Fuel Efficiency -

Furukawa Electric Co., Ltd. has developed fiber laser welding technology that controls welding defects in aluminum alloys used for automobiles. With this technology, we are contributing substantially to improving fuel efficiency through lighter automobile bodies and reduced CO2 emissions.

Background

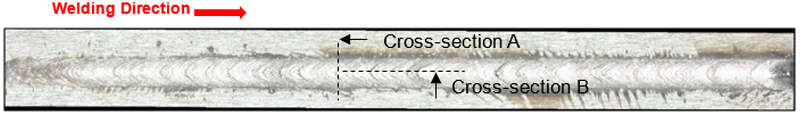

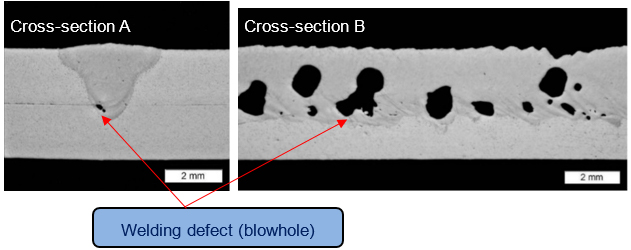

The demand for lighter automobile bodies with the goals of improved automobile fuel efficiency and reduced CO2 emissions has increased in recent years, and various types of aluminum alloys can now be used for automobile parts in an increasingly broad range of ways. Fiber laser welding, which can be expected to improve productivity by enabling high-speed, high-quality welding, is now becoming vitally necessary technology in the automobile assembly process. Meanwhile, there are technical issues to be overcome for aluminum alloy welding. Although the appearance of the welded part seems to offer a good welding surface at first glance, bead breakage and blowhole formation inside welded parts tend to occur easily.

Details

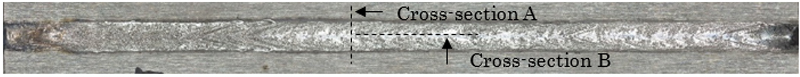

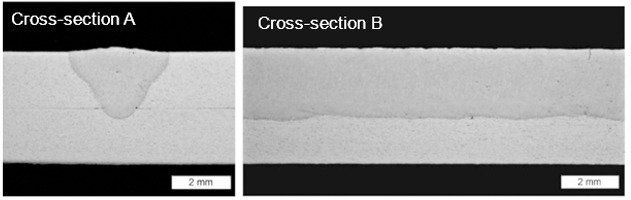

Furukawa Electric has now developed high-quality laser welding technology for aluminum alloy that increasingly broadens applications for automobile panel materials and construction materials. We have greatly reduced aluminum alloy welding defects by using the beam-mode control technology that Furukawa Electric had been developing over a long period of time as well as optimized welding conditions.

With this technological development, along with accelerating the implementation of Furukawa Electric’s fiber laser to automobile industry, we have also been working continuously to improve the welding technology of our fiber laser. It is now possible to investigate the benefits of implementing this technology at the Application Laboratory in Furukawa Electric’s Chiba Works.

Welding results of the aluminum alloy 6000 series (t=2 mm)

About Furukawa Electric Group

Furukawa Electric (TSE; 5801, ISIN; JP3827200001) Group started business in 1884, when its copper-smelting facility and wire manufacturing factory was established. Since then Furukawa Electric has become pioneers in the latest technologies by addressing diverse technological issues. Furukawa Electric has released products in a number of areas, including telecommunications, electronics, automobiles, and construction, with the three types of materials it works with at their core, namely, optics, plastics, and metals. Many of these products have attained the top global market share, and all of its products have contributed to society in numerous business areas. Furukawa Electric reported consolidated revenues of JPY 991.6 billion (approximately USD 8.9B) for the fiscal year ended March 31, 2019.

Share

Share Tweet

Tweet Share

Share