Toyota Boshoku Corporation to Adopt Aluminum Wire in Wire Harnesses for Automobile Seats

- Switch to aluminum wire to reduce weight by 44%, contributing to lighter, more eco-friendly automobiles -

- Aluminum electrical wire is adopted for the first time in wire harnesses (“WHs”) used in Toyota Boshoku seats installed in the new Toyota Land Cruiser 300.

- Using the superbly corrosion-resistant Alpha Terminal Series, aluminum electrical wire is adopted for the first time in WHs for automobile seats.

- By adopting aluminum electrical wire in 115 out of 152 circuits, weight is reduced by 44%, contributing to the improved environmental performance of automobiles.

Furukawa Automotive Systems Inc. (“the Company”; headquarters: Inukami, Shiga, Japan; president and CEO: Shigenobu Abe), a member of the Furukawa Electric Group, has installed aluminum electrical wire for the first time in WHs for automobile seats, using the superbly corrosion-resistant Alpha Terminal Series. Toyota Boshoku adopted the WHs in its automobile seats.

Background

As the list of features installed in automobiles continues to grow, automakers are increasingly searching for ways to reduce vehicle weight. Against this background, the Company is moving forward with the switch to adoption of aluminum electrical wiring in the WHs incorporated in components such as vehicle bodies and floors. Among these components are automobile seats, to which numerous features are being added, increasing the number of circuits embedded in them. In response, the Company has advanced the development of aluminum electrical wire to reduce the weight of these WHs.

Details

The Toyota Boshoku seats installed in the new Toyota Land Cruiser 300, which launched in August 2021, incorporate WHs that use aluminum electrical wiring, adopting the Company’s Alpha Terminal Series. The WHs for this model’s seats use aluminum electrical wire in 115 of 152 circuits (an aluminum adoption rate of 75%), reducing weight by 44%. The WHs used in the body, floor and other components of the new Land Cruiser 300 also have higher aluminum-wire adoption rates than previous models.

In aluminum electrical wire, to secure good electrical connections between the aluminum wire and the terminals, which are made of a different metal (usually a copper alloy), all of the terminal contacts in circuits that may come into contact with liquids must be made corrosion-resistant. This is doubly so in the case of seats, which can easily come into contact with seat cleaner, deodorizers, disinfectants and other solvents. The Company adopts the Alpha Terminal Series, which boast excellent resistance to solvents and other corrosive agents, in all aluminized circuits. In so doing, the Company became the first to incorporate aluminum electrical wire in WHs for automobile seats.

The Company intends to accelerate the aluminization of WHs for automobile seats, contributing to lower vehicle weight and improved environmental performance.

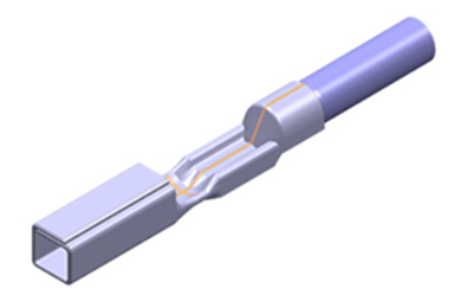

Alpha Terminal Series corrosion-resistant terminal (artist’s conception)

Product information for Alpha Terminal corrosion-resistant terminals for aluminum electrical wiring

Furukawa Electric Group’s efforts towards the SDGs

Based on the “Sustainable Development Goals (SDGs)” adopted by the United Nations, the Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to “Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.” Toward the achievement of our Vision 2030, we will take open, agile, and innovative approaches to promote ESG management that that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

Share

Share Tweet

Tweet Share

Share