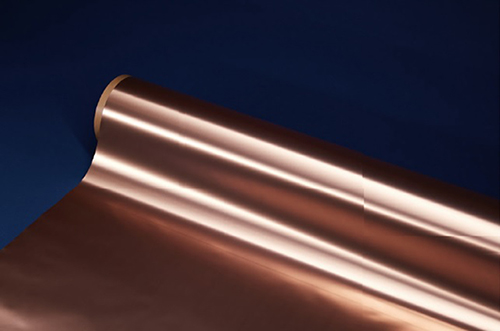

Completed UL 2809 validation for copper foil containing 100% recycled copper

- Contribute to reducing CO2 throughout the value chain directed at becoming carbon neutral -

- Copper Foil Division’s electrolytic copper foil containing 100% recycled copper has completed UL 2809 validation

- By recycling copper power cable for use in the manufacturing of electrolytic copper foil, greatly reduce CO2 emissions in the manufacturing process

- Along with the introduction of renewable energy, manufacture electrolytic copper foil with low environmental burden

Furukawa Electric Co., Ltd. (Head Office: 2-6-4 Otemachi, Chiyoda-ku, Tokyo; President: Keiichi Kobayashi) completed third party validation based on UL 2809 (Note) in July for the electrolytic copper foil manufactured at the Copper Foil Division’s Imaichi East Plant (Nikko City, Tochigi Prefecture) and Furukawa Circuit Foil Taiwan Corporation (Douliu in Yunlin County, Taiwan; hereinafter “FCFT”).

(Note) UL 2809: Validation procedure set forth by the US-based UL Solutions for environmental declarations concerning recycled content.

Background

In 2021, we announced the Furukawa Electric Group Environmental Vision 2050 and set the goal of reducing greenhouse gas emissions throughout the value chain in order to contribute to the realization of a carbon free society. In particular, as part of the “recycling-based production activities”, we have worked to manufacture cable, copper products and plastic products that use recycled raw materials from used power cable, copper strips, copper wire and plastic. The Copper Foil Division is manufacturing high performance electrolytic copper foil for collector plates in lithium ion batteries equipped in electric vehicles and printed wiring boards used in telecommunications devices such as servers, routers, mobile phones and other mobile devices.

Details

We were already manufacturing electrolytic copper foil using recycled copper power cable, but given the increased demands for recycling and decarbonization in recent years, we independently declared that our main products are “manufactured using copper foil containing 100% recycled copper” in order to enable customers to feel confident about using our products. In July of this year, we completed UL Solutions' third party validation of this claim. Our copper foil products manufactured using recycled copper make it possible to greatly reduce CO2 emissions compared to the use of electrolytic copper. For details and the subject products, please visit the UL database using the following link.

Products that have completed UL 2809 validation

<Imaichi East Plant>

DR-WS, F0-WS, F1-WS, F20-WS, F2-WS, FL1-WS, FV-WS, FWJ-WS, FWL-WS, FXJP-WS, FZ-WS, FZ-WZ, GNI-WS, GTS-STD, GTSN-STD, GT-STD, NC-WS, F1N-WS, F1ND-WS

<FCFT>

F0X-WS, F1X-WS, FZTW-WS, FX-WS, FWP-WS, FWT-WS, FT2-UP, GTS-MP, GTJ-MP, GTH-MP, GY-MP, GTSE2-MP, DGTSE2-MP, DGTSEU2-MP, DGTSEU3-MP, DX1-MP

Introduction of renewable energy at the manufacturing plants

We have switched to substantial renewable energy for the electricity used at the Imaichi East Plant from April of this year, and we are currently manufacturing electrolytic copper foil with extremely low environmental burden. In the life cycle assessment (LCA) used to evaluate the environmental impact throughout the life of the product, our products contribute to reducing CO2 emissions from procuring the raw materials to disposal or recycling of the product. We will further accelerate our efforts aimed at becoming carbon neutral and propose new value to customers by reducing CO2 emissions throughout the value chain.

Related News Releases

Furukawa Electric Group’s efforts towards the SDGs

Based on the “Sustainable Development Goals (SDGs)” adopted by the United Nations, Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to “Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.” Toward the achievement of our Vision 2030, we will take open, agile, and innovative approaches to promote ESG management that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

Share

Share Tweet

Tweet Share

Share