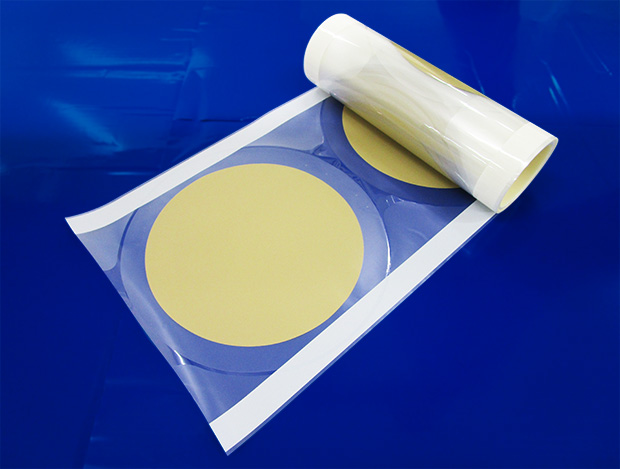

Our adhesive film is capable of transferring heat or electricity.

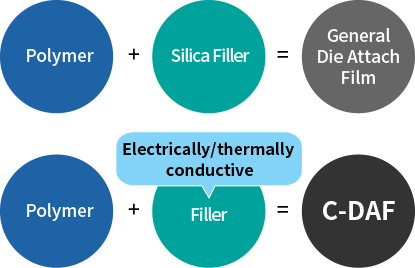

Developed using our polymer mixing and sheet manufacturing technologies, our electrically/thermally conductive dicing die attach film (C-DAF) is mixed with a special filler and continues to attract attention as a means to solve issues with heat dissipation in packages for 5G/IoT applications.

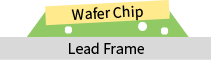

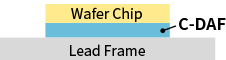

What is C-DAF?

Advantages of C-DAF

- Excellent bleed out control

- Excellent BLT(bond line thickness) control

- Less void

Features

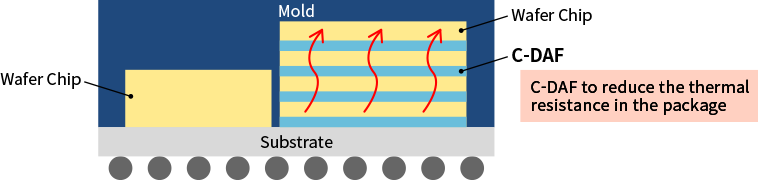

- By applying C-DAF, it is possible to reduce the thermal resistance in the package.

- For devices that has thermal constraints such as application processors, logic, PIM(Processing in memory), and power devices, we recommend a high thermal conductive type of 10 W/m*K or higher. (under development)

- If electrical insulation is required, such as for stacking in memory devices, we can propose C-DAF that does not have electric conductivity.

- We are developing a wide lineup of thicknesses from 5um to 80um or more thicker one.

- High reliability can be achieved by using an appropriate epoxy resin.

- Our C-DAF is also called as high thermal conductive epoxy film because it’s based on epoxy resin.

Click here for inquiries.