Development of “Smart Cellular Board™,” a low dielectric material for telecommunication base stations

- Promoting applications for radomes and substrates directed at realizing a Beyond 5G/6G society -

- Developed a low dielectric material that is lighter and has a lower dielectric constant and dissipation factor.

- Utilizing our original forming technology and composition development capabilities, it is possible to foam highly heat resistant plastics such as engineering plastic

- Through future product development utilizing our original technology, we will contribute to the realization of a Beyond 5G/6G society

Furukawa Electric Co., Ltd. (Head Office: 2-6-4 Otemachi, Chiyoda-ku, Tokyo; President: Hideya Moridaira) developed the low dielectric material “Smart Cellular Board™ (SCB™)” that utilizes microcellular to realize lighter weight and a lower dielectric constant (Dk) and dissipation factor (Df).

Background

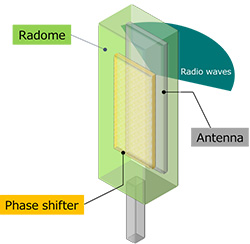

In order to realize 5G communications with characteristics including “high speed and large volume,” “high reliability and low latency” and “multiple simultaneous connections,” in addition to Sub-6 frequency, the broad, high frequency submillimeter wave band has been allocated as the communications frequency. With the planned introduction of Beyond 5G/6G in the future, it is expected that an even higher frequency broad wave band will be adopted. Given this, low dielectric materials that can more effectively transmit radio waves and signals will be required for the radome housing at base stations (cover that houses the radar antenna and protects it from the weather and sunlight), as well as for the antenna substrate and phase shifter substrate.

Details

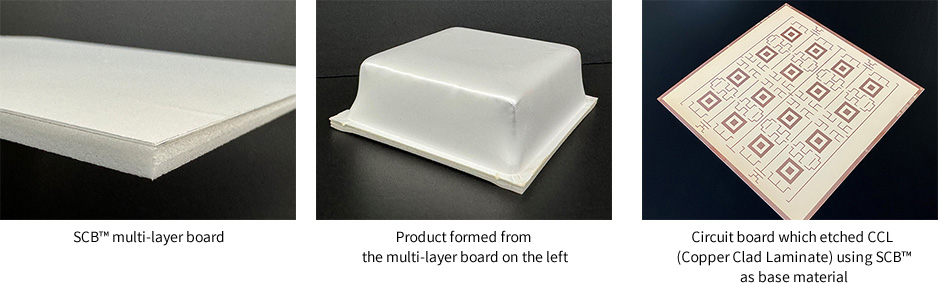

Utilizing our original technology, we have developed Smart Cellular Board™ (Fig. 2), a board type low dielectric material. It is possible to improve the dielectric characteristics of various low dielectric plastics by foaming highly heat resistant plastics such as engineering plastic and super engineering plastic. Also, because the foaming process reduces the density of the material, this new development will contribute to reducing the weight of the base station components.

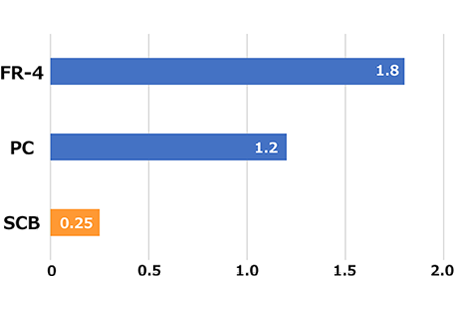

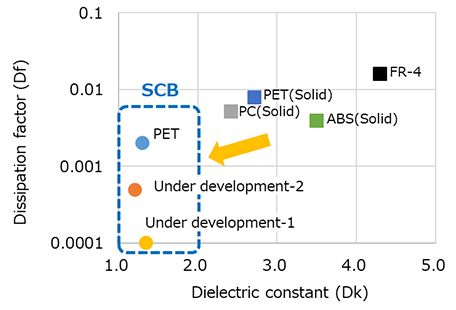

Traditionally, solid (non-foamed) plastic materials have been used for base station radomes, but Smart Cellular Board™ realizes increased radio wave permeability and a lower dielectric constant (Dk) and dissipation factor (Df) through the introduction of micro-foam. The lower density will also contribute to reducing the weight of the radome (Fig. 3 and 4). In addition, the excellent forming and machining characteristics make it possible to supply Smart Cellular Board™ in various forms (Fig. 5).

In the high frequency wave band used for Beyond 5G/6G, because the same high frequency signal will pass through the antenna and RF components at the base station, the impact of dielectric loss tends to increase compared to the traditional lower frequency signals. Also, because this dielectric loss will lead to increased heat being generated, the base station will be equipped with large heat sinks for thermal management. In response to these issues, Smart Cellular Board™ minimizes substrate dielectric loss through its excellent dielectric characteristics, and as a result, it will contribute to limiting heat generation from the substrate and reducing the weight of the heat sinks.

We will continue to contribute to the realization of a Beyond 5G/6G society through the development of products that utilize our original technology.

(Note) Dielectric loss = k × f × √Dk × Df (k: Constant, f: Frequency, Dk: Dielectric constant, Df: Dissipation factor)

“Smart Cellular Board” and “SCB” are registered Japanese trademarks of Furukawa Electric Co., Ltd. in Japan.

Product homepage

Inquiries about product

Furukawa Electric Group’s efforts towards the SDGs

Based on the “Sustainable Development Goals (SDGs)” adopted by the United Nations, Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to “Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.” Toward the achievement of our Vision 2030, we will take open, agile, and innovative approaches to promote ESG management that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

Share

Share Tweet

Tweet Share

Share