Perimeter Monitoring Radar to be Adopted in Komatsu’s New Electric Forklifts

- Optimized detection of collision warning targets according to path and speed while reversing -

- Furukawa Automotive Systems’ perimeter monitoring radar will be used in the collision detection and warning system for Komatsu's new electric forklift trucks in Japanese domestic market

- Submillimeter wave radar enables stable operation while outdoors at night/during rainy weather, in dusty work environments, etc.

- Optimizes detection area and targets for different traveling paths and speeds, e.g. reversing in a straight line or reversing while turning

Furukawa Automotive Systems Inc. (Headquarters: Inukami-gun, Shiga Prefecture; President: Shigenobu Abe), a member of the Furukawa Electric Group, announces that its perimeter monitoring radar (Model: MMR1C) has been adopted by Komatsu Ltd. as a detection sensor for the reversing collision detection and warning system of its new electric forklifts, models FE25-2 and FE30-25 in Japanese domestic market.

Background

In order to improve forklift safety, it is essential to provide functions that reduce the risk of hazards at the work site such as collision, pinching, or tangling while the vehicle is reversing, and these functions must be capable of handling the following:

- Complex conditions where there is a mix of people, cargo, and other work vehicles

- Dark environments or nighttime scenarios

- Dusty sites where water droplets, dirt, and other deposits can easily adhere to sensors

- Traveling in a straight line, turning, and other short and repeated or complex features of vehicle movement

Details

Of radar, lidar, cameras, ultrasonic waves, and other sensing methods, radar is the most suitable for forklift truck operating environments. In particular, the MMR1C submillimeter wave band (24 GHz band) is less susceptible to sensor debris, as this band has a wavelength about three times longer than that of the millimeter wave band (76 GHz band). This gives it the advantage of being suitable for use in more challenging environments.

However, it is difficult to improve target separability using the submillimeter wave band due to the narrow bandwidth allocated by the Radio Act. Within MMR1C, we have developed a process to improve target separability based on the pulse-Doppler method, which differs from the continuous-wave method.

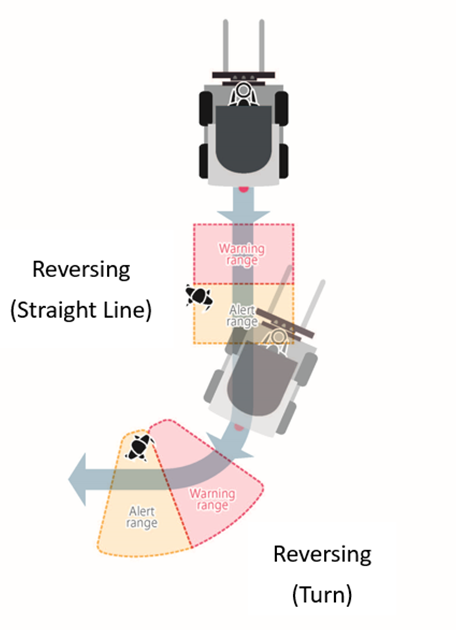

Furthermore, since simple rear sensors can be oversensitive, we have developed appropriate detection processing based on forklift-specific detection targets and vehicle movement. This has made it possible to select and detect detection areas and targets for which a warning is given depending on changes in the driving path and speed, such as when reversing in a straight line or reversing while turning.

-

Illustrative image of the detection area

based on the driving route

-

24 GHz perimeter monitoring radar

Furukawa Automotive Systems will continue to promote the installation of perimeter monitoring radars in various types of vehicles and construction equipment in order to improve the safety of construction sites and other work areas and contribute to the creation of environments where people can work with peace of mind.

Related news release

Furukawa Electric Group’s efforts towards the SDGs

Based on the “Sustainable Development Goals (SDGs)” adopted by the United Nations, the Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to “Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.” Toward the achievement of our Vision 2030, we will take open, agile, and innovative approaches to promote ESG management that that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

Share

Share Tweet

Tweet Share

Share