Starting Sales of the “BRACE™ X” Blue-IR Hybrid Laser with a 1kW blue laser

- The blue laser output is 7 times higher than the current model, and it will reduce power consumption when welding by at least 30% compared to the company’s other products -

- Sales of the new BRACE™ X blue-IR hybrid laser with a 1kW blue laser and 3kW IR laser will begin from January 2022

- Realizes high-speed welding of pure copper busbars over 2mm thick and high quality, low heat affects hair-pin welding of rectangular magnet wires used in segment conductor motors

- Reduces power consumption when welding by at least 30%, contributing to the reduction of CO2 emissions in the xEV manufacturing process toward realization of a low carbon society

Furukawa Electric Co., Ltd. (Head Office: 2-6-4 Otemachi, Chiyoda-ku, Tokyo, President: Keiichi Kobayashi) will start sales on January 26, 2022 of the BRACE™ X, a new blue-IR hybrid laser oscillator that combines a blue direct diode laser (blue-DDL) and near-infrared (IR) fiber laser.

Furukawa Electric is dedicated to advancing the operational performance of hybrid lasers, a core technology supporting electric vehicles (xEV) manufacturing, and while working to become the defacto standard in copper laser processing we will increase the production efficiency of the main xEV components and contribute to the realization of a sustainable society.

Background

Directed at becoming carbon neutral in the 2050s, efforts are being made to reduce the emissions of greenhouse gases such as CO2. From the perspective of mobility electrification, the production of essential xEV components including batteries, motors and inverters is expected to grow dramatically, and the need for laser welding that reduces manpower within the manufacturing process is increasing. High expectations exist for the use of laser welding to weld the rectangular magnet wires in segment conductor (SC) motors and to weld copper busbars over 2mm thick in the powertrain of xEV. We have already developed laser welding technology for copper combining IR fiber lasers and our independent beam mode control technology, as well as laser welding technology for pure copper with the BRACE™ I. However, there remained issues with these technologies, including the amount of spatter generated during processing and the limited range of applications compared to thickness of the material that can be welded. The newly developed BRACE™ X (Fig. 1) is equipped with a higher output blue laser and can be used for the main applications involving copper materials in xEV powertrains.

Details

Equipment specifications

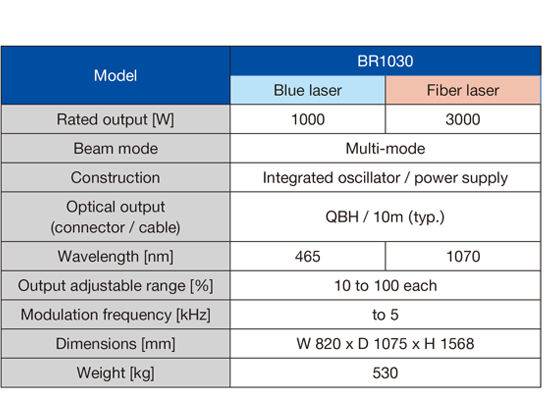

BRACE™ X (BR1030) is equipped with a hybrid laser oscillator than combines a 1kW blue laser (300μm core diameter) and 3kW IR fiber laser (50μm core diameter). The blue laser output is about 7 times higher and IR laser output is 3 times higher than the 150W blue laser and 1kW IR laser equipped in BRACE™ I (launched on January 25, 2021). By applying the high output, high reliability, high beam quality blue semiconductor laser technology newly developed by Nichia Corporation and the optical component multiplexing technology accumulated by Furukawa Electric in relation to fiber lasers, the BRACE™ X, with its 1kW blue laser (300μm fiber core diameter), is equipped with a blue DDL having one of the world’s highest optical densities of 1.4MW/cm2 (Fig. 2). Through this high light concentrating blue DDL, it is also possible to use a galvanometer scanner that can control the lasers and irradiation at high speed and simultaneously for the two wavelengths of 465nm and 1070nm. In addition, it is possible to individually activate the blue DDL and IR fiber laser, and by utilizing the beam mode control technology for the IR fiber laser, the BRACE™ X can also be used to process standard and stainless steel and aluminum, as well as weld dissimilar metals such as copper and aluminum.

The BRACE™ X will be installed in the Application Lab at the Chiba Works (Ichihara City, Chiba Prefecture) in March 2022.

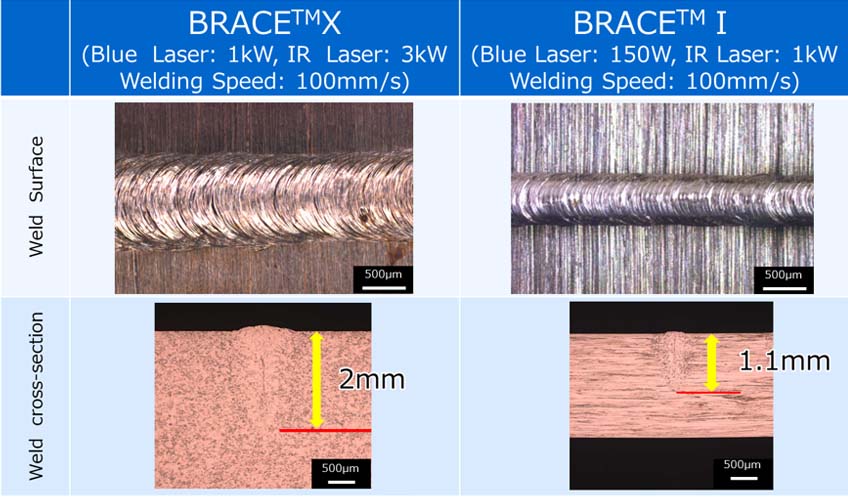

Increasing the applicable range and speed of laser welding pure copper

The BRACE™ I can weld pure copper with a thickness of less than 1mm. Possessing a maximum blue laser output of 1kW, the BRACETM X can sufficiently heat the copper material, and while expanding and stabilizing the molten pool, the IR fiber laser with a maximum output of 3kW can melt pure copper to a depth exceeding 2mm (Fig. 3). As a result, it is now possible to laser weld pure copper with a thickness of more than 2mm that is needed for use in xEV components.

Evolution of the laser welding technology for rectangular wires used in SC motors

Using a galvanometer scanner with BRACE™ X laser enables high-speed welding of SC motors using rectangular magnet wires. In addition, the stronger 1kW blue laser equipped in the BRACE™ X makes it possible to maintain the standard target laser welding speed of 0.1 s / point even when there is a gap or uneven height in the rectangular magnet wires being joined. Also, the spatter generated during welding can be reduced by controlling the heat input from the blue laser, thus reducing the impact on areas outside of the weld. Because the overall laser output can be lowered, along with reducing the impact on the insulation layer when welding rectangular magnet wires of SC motors, power consumption can be reduced by about 30% compared to our existing 6kW fiber laser (FEC6000M).

Upcoming exhibitions

| Date | December 8, 2021 (Wed.) – December 10 (Fri.) |

|---|---|

| Venue | Makuhari Messe, Hall 8 |

| Booth | 56-54 |

Related news releases

Furukawa Electric and Furukawa Develop World-leading Laser Welding Technology for Pure Copper

Launching Sales of the “BRACE™” Blue-IR Hybrid Laser

New Laser Welding Machine for Motors of Electric Vehicles (EV) Developed

Related website

Furukawa Electric Group’s efforts towards the SDGs

Based on the “Sustainable Development Goals (SDGs)” adopted by the United Nations, the Furukawa Electric Group has formulated the “Furukawa Electric Group Vision 2030” which sets the year 2030 as its target and is advancing efforts with the aim to “Build a sustainable world and make people’s life safe, peaceful and rewarding, Furukawa Electric Group will create solutions for the new generation of global infrastructure combining information, energy and mobility.” Toward the achievement of our Vision 2030, we will take open, agile, and innovative approaches to promote ESG management that that aims to increase corporate value over the medium to long term and will contribute to the achievement of the SDGs.

Share

Share Tweet

Tweet Share

Share